1942 - 1947 CHEVROLET SHOP MANUAL

Section 2 - Frame

|

|

|||

|

2-8 |

|||

|

|

|||

|

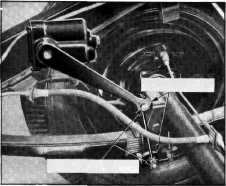

These shock

absorbers are also mounted on the car

frame side member and the operating arms connected to the axle through suitable

linkage. While this linkage

varies in construction between front and rear installation, operation of

the two shock absorbers is

identical. The method of mounting the front shock absorber on passenger

car models is shown in Fig. 10,

and that of rear shock absorbers in Fig. 11. A detailed

description of the front shock

absorber link attachment to the front suspension is given in Section 3 of this

manual. |

The upper

piston moves to the right, Fig. 9, displacing the fluid in the rebound cylinder.

In slow action, the fluid flows

only through the orifice of the rebound valve into the compression end

of the compression cylinder. During rapid action the rebound valve is

lifted from its seat and the fluid is forced into the compression

cylinder. At the same time the intake

valve of the compression piston opens allowing fluid to pass from the

reservoir into the cylinder

thus compensating for any loss of fluid between piston and cylinder walls of

the rebound cylinder.

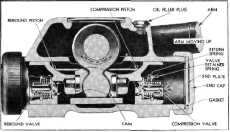

OPPOSED CYLINDER DOUBLE-ACTING

SHOCK

ABSORBERS

INTERNAL VALVE TYPE

A cross section view of the

opposed cylinder double-acting type shock absorber is shown in Fig. 12.

This is one of the types available as special equipment on truck

models. |

||

TAPERED HOLES IN ARM

AND ANCHOR

PLATE TAPERED LINK PIN VULCANIZED TO RUBBER IN LINK

EYES |

|||

|

|||

|

Fig. 11—Passenger Car Rear Shock Absorber

Mounting

The rear

shock absorber arms are attached to a link incorporating tapered link studs

vulcanized to rubber grommets

in each eye, Fig. 11. The tapered link studs fit horizontally into a

tapered hole in the arm and

vertical section of the axle fitting. Hexagon nuts hold the studs securely in

position.

Operation

Upon

compression of the car springs, the arm moves upward on the compression stroke

forcing the piston in the

compression cylinder, Fig. 9, toward the right. For very slight or slow axle

or wheel movement, the fluid

flows only through the orifice

of the compression valve, as indicated by the black dotted arrow, and into the rebound

end of the shock or rebound

cylinder. Under rapid movement of the axle or wheels the pressure

lifts the valve from its seat

by compressing the compression valve spring, thus forcing the fluid into

the rebound cylinder. At the

same time, the intake valve of the rebound piston opens, allowing fluid to

flow from the reservoir into

the rebound cylinder. This is to compensate for any loss of fluid between

piston and cylinder walls from the compression cylinder into the reservoir.

During the

rebound stroke, or as the arm moves downward, the direction of fluid flow is

reversed. |

|||

|

Fig. 12—Opposed Cylinder

Double-ActIng Shock Absorber with Internal Valves

Inside of

the body and pressed on the shaft is a cam which bears against one piston

during compression and the other during rebound movement. The two pistons are held together by two

screws, one in each piston,

that pass through one piston and thread into the

other.

The fluid reservoir is the space

surrounding the shaft and cam inside the body, and an easily

accessible filler plug is located in the upper part of this chamber. An end cap and plate with gasket is

threaded over each end of the

body and must be removed for

making valve changes.

On this type of opposed cylinder

shock absorber the relief and intake valves are both placed in the pistons. The rebound and compression valves

operate as main control valves

and also as inlet valves for

the return of fluid to each cylinder,

Operation-

The shock

absorber unit comprises one rebound and one compression piston, the rebound

piston being fitted with a

spring-loaded rebound valve |

|||

|

|

|||