1942 - 1947 CHEVROLET SHOP MANUAL

Section 3 - Front Suspension, Axle & Springs

|

|

|||

|

3-12 |

|||

|

|

|||

|

SETTING TOE-IN |

|

||

|

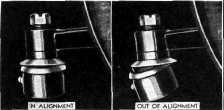

Toe-in can

be adjusted by loosening the clamp bolts at each end of the left hand tie rod

and turning the tie rod to increase its length until proper toe-in is secured. Before locking

the clamp bolts make sure that

the tie rod ends are in alignment with their ball studs, Fig. 28. If the

tie rod is not in alignment

with the studs, binding will result. Lock the clamp bolts at each

end of the tie rod

securely. |

|||

|

|||

|

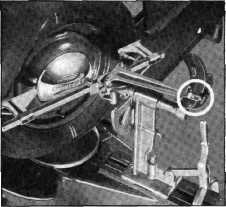

Fig. 29—Wheels Set IN 20 degrees for Checking Steering

Geometry

toe-out on the right wheel which

should be 24 degrees plus or minus 2 degrees.

To check

the left steering arm, turn the right wheel in 20 degrees and repeat the

operations described above. If the left wheel does not have the

proper amount of toe-out,

replace the left steering arm.

If the right wheel does not have the proper amount of toe-out, replace the right

steering arm.

This completes the checks and

corrections. However, it is good

practice to recheck all the angles after corrections have been

completed to assure accuracy. When

checking and correcting the front end angles of any car the factory

specifications should be closely adhered to. |

|||

|

Fig. 28-Alignment of Tie Rod Ends

STEERING GEOMETRY

Steering

geometry or toe-out on turns is controlled by the angle of the steering arms.

Therefore, checking the

steering geometry determines whether or not the steering arms are bent. To check

the right steering arm, turn

the left wheel in so that when

the contact bar of the aligner engages the tire, the pointer will set at 20 degrees,

Fig. 29. Now go to the right

side of the car and push the contact bar in until it engages the tire. The

pointer on the right hand scale

will now indicate the amount of |

|||

|

|

|||

|

FRONT AXLE ASSEMBLY

1/2, ALL 3/4 AND 1-1/2-TON TRUCKS |

|||

|

|

|||

|

CONSTRUCTION

The front

axle used in the 1/2, all 3/4 and 1-1/2-ton trucks is known as the reverse Elliot

type. It is a steel dropforging with the spring seats forged integral with the "I" beam. The "I" beam is

heat-treated for extreme

toughness and is machined to very close limits.

The

kingpin is recessed and held in position by a tapered pin drawn tightly into the recess

by a lock washer and nut. The

holes at each end of the "I"

beam are bored at a slight angle to permit the kingpin to tilt inward at the top. This

inward tilt is called kingpin

inclination.

The

steering knuckle is mounted to the front axle, by means of this kingpin, and rides

on a ball bearing which makes

steering easy.

The brake

flange plate is securely bolted to the

steering knuckle and carries the brake shoes and wheel cylinders. The steering knuckle

arms |

are also

bolted to the steering knuckle and are connected with each other by the tie rod. The

tie rod is the adjustable type

attached to the knuckle arms and controls the amount of forgather or

toe-in of the front

wheels.

The

steering third arm is forged integral with the left knuckle arm and is connected to the

pitman arm by the steering connecting rod.

A caster

shim or "I" beam spacer is inserted between the front springs and the front

axle. The installation of this

shim controls the amount the top of the axle inclines or tilts backward.

This backward tilt of the axle

gives the front wheels their

caster.

The front

wheel spindles, forged integral with the steering knuckles, are tilted downward

at their outer ends, causing

the front wheels to be farther apart at the top than they are at the

bottom. This slight angular

position of the front wheels is called camber. |

||

|

|

|||