1942 - 1947 CHEVROLET SHOP MANUAL

Section 4 - Rear Axle, Universal Joints & Springs

|

|

|||

|

4-23 |

|||

|

|

|||

|

the left bearing, at the same time

fitting the shifter yoke to the groove in the shifter sleeve.

Install

the double reduction shaft bearing outer race in the right side of the carrier and

tap it in flush with the

carrier.

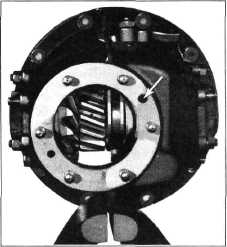

Install a

new gasket on each side, and then install the same number and thickness of shims

that were removed when

disassembling, making sure the

cut-out in the gasket and shims line up with the lubrication openings in the housing,

Fig. 46.

Assemble

the bearing caps, being careful to line up the lubrication openings in the cap with

those in the carrier. Install three lockwashers and nuts on each cap, evenly spaced, and tighten

them securely.

Install

the shifter yoke shaft bushing over the shaft and tap it into the carrier. Then

install the cork seal in the top of the bushing. Assemble

the |

|

||

|

|||

|

Fig. 47-Pinion Cage Oil Holes

first in

one direction and then the other, at the same time applying pressure on

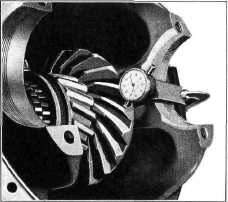

the back of the ring gear to bring a

load on the gears.

Then check

the tooth bearing on the ring gear for

pinion depth. If the pinion is too deep the tooth bearing will be below the pitch line.

If it is too shallow, the

bearing will be above the pitch line.

To make

pinion depth adjustment, remove the pinion cage and—

1. Add shims between cage and carrier if the

pinion is too

deep.

2. Remove shims if the pinion is too shallow.

Excessive backlash between the

ring gear and |

|||

|

Fig, 46—Installing Double Reduction Shaft Bearing Cap

Shims

shift lock

spring and pawl. Install the Woodruff key in the shaft, shift lever, shakeproof

lockwasher and nut Tighten the

nut securely.

Check the

bearing adjustment. Correct adjustment of the double reduction shaft bearings

will produce a slight "drag"

when it is turned by hand. Bearing adjustment is secured by the use

of shims of .003" and .005"

thickness.

Assemble a new pinion cage gasket

and the same number and thickness of shims that were removed when disassembling. Be careful to line up

the oil holes.

Assemble pinion cage and pinion

assembly to the carrier with the

lubrication fitting in the cage to the top right side, being careful to line

up the oil holes, Fig. 47.

Install three lockwashers and nuts evenly spaced and tighten them

securely.

Adjustment

Paint the

ring gear with red lead, or coat it lightly with prussian blue. Turn the drive

pinion |

|||

|

|||

|

Fig. 48—Checking Backlash |

|||

|

|

|||