1942 - 1947 CHEVROLET SHOP MANUAL

Section 4 - Rear Axle, Universal Joints & Springs

|

|

|||

|

4-26 |

|||

|

|

|||

|

|||

|

|

|||

|

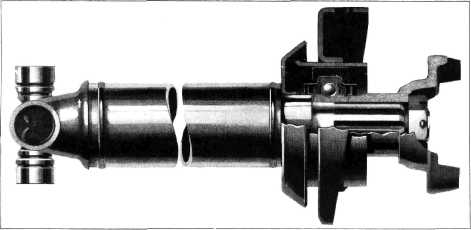

Fig. 52—3/4-Ton Long W.B., 1-1/2-Ton and C.O.E. Front

Propeller Shaft and Support |

|||

|

|

|||

|

SPEEDOMETER

ADAPTER

A speedometer adapter is used to

secure proper speed and odometer readings with the rear axle in either high or low speeds. The shift rod

which shifts the gear ratios in the adapter is connected to the

axle shift lever so that whenever a change in ratio is made at the rear axle a

corresponding change is made in the speedometer

adapter.

PROPELLER SHAFTS

Because the

passenger car and 1/2-ton commercial cars use the torque-tube drive

principle, while all 3/4-ton, 1-1/2-ton heavy duty and C.O.E,

trucks have the Hotchkiss, drive,

service operations on the various units vary according to the type

drive used.

Service

operations on the passenger car and 1/2-ton commercial car propeller shafts are

covered in the first part of this section.

4-TON LONG WHEELBASE PANEL,

1-1/2-TON HEAVY DUTY AND C.O.E. TRUCKS

The drive

line from the transmission to the rear axle comprises two tubular propeller shafts

and three needle bearing

universal joints. On the front propeller shaft the rear yoke of the front

universal joint is an integral part of the propeller shaft. The

rear end of this shaft is machined to

receive the support bearing, and it is also splined and threaded

to mount the front yoke of the

intermediate universal joint, Fig. 52.

The

support bearing is mounted in the support bracket by means of a rubber cushion which

fits over the outer race of the

bearing and inside a |

sleeve in

the support bracket. This bearing is of the permanently lubricated and sealed

type.

On the rear

propeller shaft the front yoke of the rear universal joint is an integral

part of the propeller shaft. The

front end of this shaft is splined to fit the splines in the rear

yoke of the intermediate

universal joint.

UNIVERSAL JOINTS

All three

universal joints are of the needle bearing type. The front and rear yoke of each

universal joint is machined to receive the trunnion bearings. The bearings are anchored to the front yokes

of the front and intermediate universals and the rear yoke of the rear universal by "U" clamps.

The bearings in the rear yokes

of the front and intermediate universals and the front yoke of

the rear universal are pressed into the yokes and locked by snap rings. The front yoke of the front

universal is splined to the

transmission main shaft, and the rear yoke of the rear universal is splined

to the rear axle drive

pinion.

Each

trunnion is drilled and fed by a central lubrication fitting for lubricating the

bearings, Fig. 53. On the side

opposite the lubrication fitting, a relief valve is mounted. This valve is

adjusted to "pop" at from 40

to 80 pounds' pressure, thereby preventing over-lubrication or

damage to the trunnion bearing

seals.

A

lubrication fitting is mounted on the rear yoke of the intermediate universal to lubricate

the splines, Fig. 53. A plug

is staked into the forward end

of the splined opening to retain the lubricant. A small hole is drilled in the center of

this plug to relieve trapped air. The rear end of the

splined |

||

|

|

|||