1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

||||

|

6-53 |

||||

|

|

||||

|

Tighten all manifold bolts, valve

rocker shaft support bolts and nuts.

Valve stems should be lubricated

with light engine oil to make sure they are not sticking—this is

important.

Intake valve clearance should be

adjusted to a minimum of .006" to a maximum of .008" hot.

Exhaust valve clearance should be

adjusted to a minimum of .013" to a maximum of .015" hot.

Regular attention will practically

eliminate cooling system troubles. The most logical times for

cleaning and reconditioning the cooling system are:

1. When anti-freeze is installed in the

fall.

2. When anti-freeze is removed in the

spring.

CLUTCH

CONSTRUCTION

The clutch on all passenger car

and trucks is the single plate dry disc type, designed around a diaphragm

spring having the shape of a dished |

engaged, the fingers are flat and

the entire rim of the diaphragm spring exerts pressure against

the |

|||

|

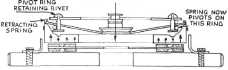

SPRING PIVOTS ON THIS PIVOT

RING |

||||

|

||||

|

Fig. 110—Engaged Position of

Diaphragm Spring

pressure plate, Fig. 110. When the

clutch pedal is depressed, pressure of the throwout bearing on the inner

ends of the fingers causes a diaphragm action and the outer ends of the

fingers, near the rim, pivot on the inner pivot ring. Fig. 111. This

action |

||||

|

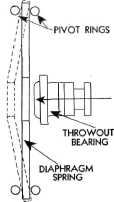

THROWOUT BEARING FORCES SPRING IN

THIS DIRECTION |

||||

|

||||

|

||||

|

Fig. 111—Disengaged Position of Diaphragm Spring

causes the rim of the spring and

the pressure plate to move back away from the clutch disc,

disengaging the clutch. When the clutch pedal is released and the

throwout bearing no longer contacts the fingers, the "spring" in this

material causes the fingers to pivot about the rear pivot ring and the rim

to bear against the pressure plate.

Clutch Noises

A rattling noise in the clutch

assembly at idling speed with the clutch released may be caused by

insufficient tension on the pressure plate retracting springs. This noise

can be easily remedied by replacing the retracting springs as

follows:

1. Remove the clutch housing

under-pan.

2. Hand-crank the engine until one retracting

spring attaching bolt is at the

bottom. Remove the bolt and

retracting spring and install a new spring.

3. Replace the other retracting springs in the

same manner as described

above.

Should the above not correct the

rattle, the clearance between the drive lugs on the pressure plate and the

slots in the clutch cover should be checked. If this clearance exceeds

.010", the pressure plate and/or cover assembly should be

replaced, to obtain proper clearance. |

||||

|

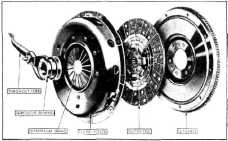

Fig. 108—Layout of Clutch Parts

washer with eighteen tapering

fingers pointing inward. Fig. 108. The

|

||||

|

spring is made from very high

quality steel, carefully heat-treated and shot-blasted to assure long

life. The action of the diaphragm spring may be compared to the flexing action of the bottom of

an ordinary oil can. By depressing the clutch pedal, the throwout bearing is forced against

the diaphragm spring fingers, causing the diaphragm spring to pivot

on the pivot rings, Fig. 109 When the clutch is |

Fig. 109—Action of Diaphragm Spring |

|||

|

|

||||