1942 - 1947 CHEVROLET SHOP MANUAL

Section 8 - Fuel Tank & Exhaust System

|

|

|||

|

8-1 |

|||

|

|

|||

|

Section

8

FUEL TANK AND EXHAUST

SYSTEM |

|||

|

|

|||

|

FUEL TANK

PASSENGER CARS AND

SEDAN DELIVERY

The fuel

tank on these models consists of two shallow pans, each with a wide flange. The

pans. set face to face, are seam welded at the flanges around the

entire tank to assure leak-proof construction. Exceptional stiffness is secured

by the combination of the

welded flanges and depressed ribs in each of the

pans.

On all 5-passenger cars the fuel

tank is mounted by straps to the

underbody of the trunk compartment to insure sufficient road

clearance.

The outlet

pipe and that portion of the feed pipe connecting to the outlet pipe flange

have a downward slant toward

the tank, to eliminate the possibility of water or moisture

accumulating at this point. Upper and lower filler necks are so treated

that rust will not get into the fuel supply.

To remove

the tank, disconnect the filler neck at the coupling. Then disconnect the main

gasoline pipe and the gasoline gauge wire. Remove the strap bolts, nuts, washers and spacers and lower

the tank.

The fuel

tanks on the Business Coupe and Sedan Delivery incorporate baffle plates which

act as stiffeners and prevent

the surging of gasoline within the tank.

The general construction of the

Business Coupe and Sedan Delivery fuel

tank is quite similar to that used on other passenger cars,

however, it is mounted differently to make better use of the load-carrying space in these

models.

The tank is located crosswise

under the loading floor, resting on

two wooden spacers which are bolted lengthwise to the floor pan. Two

straps in line with the spacers

clamp the tank rigidly in place. At the front end, each strap hooks

into a bracket which is bolted to the wooden riser behind

the seat and is also welded to the

floor pan. The rear of each

strap is attached to an eye bolt that extends through the spacer and the floor

pan. The filler passes through

the body panel just ahead of the rear fender on the curb side of the

car. The tank is readily

accessible through the cover board in the loading floor. In replacing the tank

care should be used to make sure that the sponge rubber seal at the outlet is in place and that the

sponge rubber mat is properly

located on top of the tank. |

This mat

compresses against the top of the tank and guards against noise at this

point.

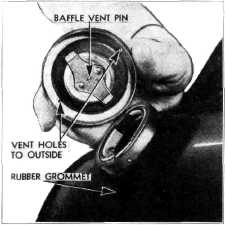

FUEL TANK FILLER CAP

To prevent

spilling of gasoline when making sharp

turns or traveling on rough roads, a device, consisting of a baffle cup and a vent pin

is incor-porated in the filler cap, Fig. 1. Through this

arrangement the vent area is reduced to a minimum, yet is large enough to serve as a

breather for the fuel tank.

The small vent area is accomplished by inserting a special pin in the

breather holes which are kept open by the bouncing or "jiggling" action of the pin. This minute

area, if pierced in the outer

part of the cap as a separate hole, would soon be clogged by dirt

or corrosion. |

||

|

|||

|

Fig. 1—Fuel Tank Filler Cap

The device

not only controls the flow of gasoline, but also traps in the baffle cup any

that might escape through the

lower vent. The chamber volume

is adequate for the ordinary overflow, which subsequently returns to the tank. A

small hole is provided at the

top of the chamber to complete the breather

system.

A slight

clearance must be maintained between the filler cap and the rubber grommet

around the filler neck, particularly

on passenger cars, to prevent the cap "bottoming" or sealing against

the rubber. When this occurs,

the vent is cut off en- |

|||

|

|

|||