1942 - 1947 CHEVROLET SHOP MANUAL

Section 9 - Steering Gear Assembly

|

|

|||

|

9-7 |

|||

|

|

|||

|

|||

|

|

|||

|

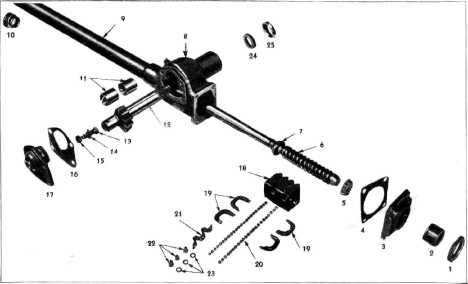

Fig. 15—Layout of Truck Steering Gear

Parts |

|||

|

|

|||

|

1

Worm Bearing Adjuster

Lock Nut

2

Worm Bearing

Adjuster

3

Housing End

Cover

4

End Cover

Gasket

5

Lower Wormshaft Roller

Bearing 6 Wormshaft Assembly

7

Upper Wormshaft Roller

Bearing

8

Housing

9

Mast Jacket

10 Mast Jacket Bearing

Assembly

11 Sector Shaft Bushings

12 Sector and Shaft

13 Lash Adjuster |

14 Lash Adjuster Shim

15 Check Nut 7/16-20

16 Housing Side Cover

Gasket

17 Housing Side Cover and Bushing

Assembly

18 Ball Nut

19 Ball Guides

20 Balls

21 Ball Guide Clamp

22 Bolt 1/4-20

23 Lockwasher 1/4

(Internal)

24 Sector Shaft Packing

25 Sector Shaft Packing

Retainer |

||

|

|

|||

|

the straight-ahead position, and

still maintain perfect freedom

at extreme right or left positions of the wheels.

Through

the design of the teeth on this sector, the slight wearing-in of the teeth in the

straight-ahead position, which

may occur during the long life

of the sector teeth, can be taken up by adjustment without causing a

"binding" condition in the less-used portion of the sector teeth

toward either end from the straight ahead position.

CAB-OVER-ENGINE TRUCKS

Cab-Over-Engine trucks

are equipped with a heavier steering gear for greater strength and durability. The ratio is 23.6 to 1. The

general design of this steering gear is the same as that used

on the conventional trucks,

recirculating ball type. except that 106 balls of 9/32"

diameter (53 in each circuit) are used instead of 60 as on the

other models. The greater

number of balls in this model |

steering

gear results in more of them in working contact at all times. All parts affected by

this greater number of balls,

the worm, nut, worm bearings,

etc., are correspondingly larger than on the conventional trucks.

■

This

steering gear is mounted in a frame bracket at the front end of the left

side rail, Fig. 16. The pitman arm is

forward of the steering arm. making it necessary that the steering connecting

rod be assembled with the

offset to the front of the truck, with the lubrication fitting on top, to

provide proper tire clearance

on turns.

The

wormshaft is tubular on this model and the horn wire is soldered to a contact ring

pressed onto and insulated

from the wormshaft as shown in Fig. 17. The wire passes through the

tubular shaft and is soldered to a

contact sleeve insulated from the shaft by three fiber washers at the top

end of the wormshaft. A spring

loaded contact brush is |

||

|

|

|||