1942 - 1947 CHEVROLET SHOP MANUAL

Section 2 - Frame

|

|

|||

|

2-4 |

|||

|

|

|||

|

|||

|

|

|||

|

|||

|

|

|||

|

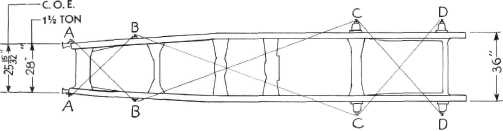

Fig. 5- 1-1/2-Ton Conventional 160" Wheelbase

Frame |

|||

|

|

|||

|

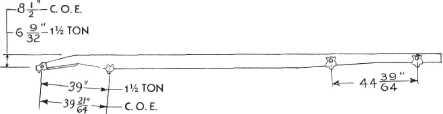

3/4-TON LONG W.B. PANEL AND

134-1/2" W.B. 1-1/2-TON TRUCKS |

CHECKING FRAME ALIGNMENT

When checking a frame for

misalignment in case of damage, the

most efficient method is "X" checking with a tram from given points on

each side rail.

In the

Figures 1. 2, 3, 4 and 5, reference points are indicated—"A," "B," "C" and "D" on

each

frame side member.

When

making checks on all conventionally sprung models, the tram points should be set

at the renter of the

lubrication fittings. When checking the front section of independent

suspension models, the check should be made from the center of the front bumper bracket bolt to the

center of the body bolt at the

front body mounting bracket, shown by lines "AB" in Figs. 1 and

2.

When "X"

checking any section of the frame, the

measurements should agree within 5/16". If the measurements do not agree within the above

limit, it means that

corrections will have to be made between those measurement points that are

not equal.

The minimum

dimensions between the spring hangers, both front and rear, are also

shown on the illustrations. In

addition the height of the front spring horns with reference to the top of

the frame side member is shown

on the truck model illustrations. |

||

|

The 3/4-ton long Wheelbase panel

and 134-1/2" Wheelbase 1-1/2-ton truck frames are identical with exception to a slight difference in the

brake cross shaft bracket. Each

frame has five cross members.

1-1/2-TON 160" AND 195-1/8"

W.B. AND C.O.E. TRUCKS |

|||

|

Five cross

member frames are used on the and

132-5/8" Wheelbase 1-1/2-ton C.O.E. trucks; six cross member frames on the 160" Wheelbase

conventional and 158-1/8" Wheelbase 1-1/2-ton C.O.E. trucks. The 195-1/8"

Wheelbase l-1/2-ton

conventional school bus frame

has eight cross members.

All

Cab-Over-Engine 1-1/2-ton truck frames include a sub-frame at the front end to

provide proper clearance for

the cab mounted over the engine.

STRAIGHTENING THE FRAME

In the case of a collision or

accident where the bending or

twisting of the frame is not excessive, it is permissible to straighten the frame.

This must be done cold, as

heat applied to the frame will

change the structure of the metal and weaken the frame at the point where heat is

applied. |

|||

|

|

|||