1942 - 1947 CHEVROLET SHOP MANUAL

Section 3 - Front Suspension, Axle & Springs

|

|

|||

|

3-17 |

|||

|

|

|||

|

|

||

|

|

|||

|

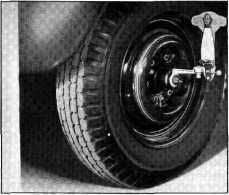

Fig. 38—Checking Kingpin Camber

KINGPIN INCLINATION CHECK

1. Turn the wheel on which the check is being

made OUT

25°.

2. Set the gauge on the spindle with the scale

turned parallel to the

wheel.

3. With the pointer on the gauge set at zero,

turn the gauge on the spindle

until the bubble in the level

is centered.

4. Now turn the wheel IN 25° and adjust the

gauge until the bubble in the

level is centered and read

the amount of kingpin inclination on the scale. Fig. 39.

STEERING GEOMETRY

Steering geometry or front wheel

toe-in and toe-out on turns is controlled by the steering arms in the same

manner as on passenger cars, and checking this determines whether or

not the steering arms are bent. Both of these checks are made on truck

front axles using the "Jiffy" J-751 turntables in a manner similar to the

passenger car on the front end machine.

With the front wheels resting in a

straight-ahead position on the turntables, and the pointer of each

turntable set on zero, check the right steering arm by turning the left

wheel in so the pointer rests on the 20 degree mark; the pointer on the

right wheel turntable will now indicate the amount of toe-out which should

be 23 degrees, plus or minus 2 degrees, on all trucks. To check the

left steering arm, turn the right wheel in 20 degrees and repeat the

operation described above for checking the right steering

arm.

When the right wheel does not have

the proper amount of toe-out, replace the right steering arm. When this

condition exists on the left wheel, replace the left steering

arm. |

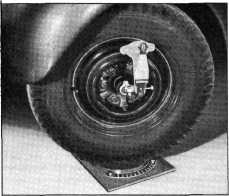

Fig. 39— Checking Kingpin

Inclination

TOE-IN

Front wheel toe-in is checked

using the J-710-0 Toe-In Gauge, measuring first at the rear of the axle on

the front tires, then, after rolling the car forward, at the same point on

the tires which will now be at the front of the axle. The variation as

shown on the gauge is the amount of toe-in or toe-out. The proper toe-in

is 5/64" to 1/8" for all truck models. To adjust or set the toe-in,

loosen the clamp bolts at each end of the tie rod and turn the rod as

necessary to arrive at the correct toe-in.

CORRECTING FRONT-END

ALIGNMENT

CASTER CORRECTION

Caster corrections in ordinary

amounts may be made with the use of caster shims. To increase caster,

place the thick side of the shim toward the back between the spring seat

and the spring. To decrease caster, place the thick side of the shim

toward the front. The maximum amount of caster correction that should be

made with the use of shims is 2° and anything over this amount

should be corrected with the use of Correcting

Tools. |

||

|

|||

|

Fig. 4D—Decreasing Caster on Right

Sid* |

|||

|

|

|||