1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

|||

|

6-10 |

|||

|

|

|||

|

tion and

endwise movement. They are accurately line reamed at the time of assembly,

assuring proper alignment of

the camshaft. These bearings are lubricated through holes which line up

with the oil passages leading

from the main bearings.

To remove,

replace, and line ream the camshaft bearings in service; a set of special tools

is necessary. This set

consists of a removing and replacing bar, four removing and replacing

sleeves, a bracket which is

attached to the rear of the cylinder block and a special camshaft bearing

reamer shown in Fig. 16. These

are the same tools that have

been used since the 1937 model for replacing camshaft

bearings. |

||

|

|||

|

Fig. 16—Camshaft Bearing Removing and Replacing

Toots

1 Reamer

4 Extension

Handle

2 Removing and

Replacing 5 Bracket

Bar

6 Handle and

Thrust

3 Removing and

Replacing

Bearing

Sleeves

7 Staking Tool

Camshaft Bearing Removal

1. After removal of the camshaft, drive out

the expansion plug from the

cylinder block at the rear of

the rear camshaft bearing, by driving it out from the inside.

2. Assemble the camshaft bearing remover

bracket loosely to the rear of

the cylinder block.

3. Start the bearing puller bar through the

front bearing and install the puller sleeve for each bearing over the bar

before it passes through that

particular bearing. Then pass the bar through the hole in the bracket. Tighten the

bolts that hold the bracket to

the Crankcase. Then install the

thrust bearing and puller handle on the end of the

bar.

4. Turning the puller handle clockwise will now

remove all four bearings at one

time. An extension handle

is provided to aid in starting bearings that may have corroded in the

case.

Camshaft Bearing Replacement

1. To make

sure that the oil holes in the camshaft bearing bores will line up with the oil

holes in the camshaft bearings

after the bearings have

■ been

installed, mark the position of the oil hole in the bore on the front face of the bearing

bore. |

|||

|

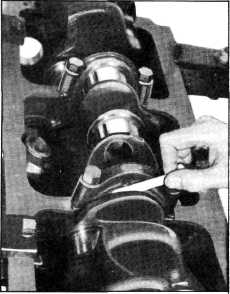

Fig. 15-Checking Crankshaft End-Ploy

(turning it

by hand) with the bolts pulled down tight. Then replace one .002" shim on one

side for clearance, again tighten the bolts and check for drag. The crankshaft should now roll freely

without any indication of

a drag.

Loosen the

bolts on the bearing that has just been adjusted and proceed to adjust the next

one in the same manner and so on until all bearings have been adjusted.

When

adjusting the bearings, shims should be removed evenly. If an uneven number of

shims have to be used, it is

good practice to have the greater number of shims on the same side

of all bearings.

By

following the procedure of removing shims to check and then replacing one .002" shim,

there will be no possibility

that the bearing will be too loose. Then if the crankshaft may be turned

freely by hand, it is certain that the bearing is not too tight.

If the

shaft turns freely by hand, after all bolts have been tightened, you know the bearings

are properly

adjusted.

CAMSHAFT BEARINGS

All four

of the camshaft bearings are steel backed, babbitt lined. They are pressed into

the crankshaft and staked into

place to prevent rota- |

|||

|

|

|||