1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

|||

|

6-24 |

|||

|

|

|||

|

Valve

spring cap covers, of an umbrella type are used on all intake valve stem ends. The

cap covers are designed to

carry the oil which flows down

the rocker arms to lubricate the valve end of the arms, out over the intake valve spring.

This reduces the amount of oil

reaching the intake valve stems for guide lubrication to only that

amount required for proper

lubrication, thus controlling oil consumption and smoking when the engine is

idling.

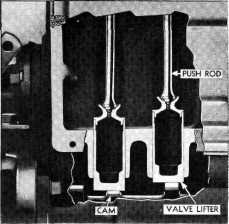

VALVE LIFTERS AND PUSH RODS

Chevrolet

valve lifters are made in two parts. The lower part is machined from a casting,

the bottom of which is chilled during the casting operation to produce a hard wearing surface.

The Upper part, incorporating

the push rod seat, is machined

and hardened to produce a smooth, long-wearing seat. The lifter unit is completed

by brazing the steel seat

into the cast part of the lifter. Fig. 51 shows the construction of the lifter

in cross-section. |

ROCKER ARMS AND SHAFTS

The valve rocker arms are made of

a newly developed metal known as Armasteel which reduces wear of

these parts to a minimum. The ends contacting the valve stems are especially

hardened. The rocker arms are

diamond bored and bear directly on the rocker arm shafts. After

boring each arm is given a wear resisting coating for protection against scuffing or scoring during the

break-in period.

Due to the

combustion chamber design and valve

positions, all rocker arms are offset at an angle. There are four different types of

rocker arms used; right and

left hand angle intake arms, and right and left hand angle exhaust. None

of these rocker arms are

interchangeable, one with the other nor with previous models other than

1941, and care must be used

when assembling the rocker arms to the rocker arm shaft to place

each arm in its correct position to

line up with the valve it is to

operate. |

||

|

|

|||

|

|

||

|

Fig. 52—Valve Rocker Arm Identification

Each type

rocker arm carries a different part number and for identification purposes a

number (I, 2, 5 or 6) is cast on the side of each arm,

Fig. 52.

The following chart shows rocker

arm identification numbers as

well as the type, where used and the part number.

Number on Type

Part

Rocker Arm Rocker Arm For Cylinder Number

1 L. H.

Exhaust 1-3-5 Exhaust 839459

2 R. H.

Exhaust 2-4-6 Exhaust 839460

5 L. H.

Intake 2-4-6 Intake 839463

6 R. H.

Intake 1-3-5 Intake 839464

The rocker

arms, springs and shaft supports are assembled to the rocker arms shafts and

locked in place with hair pin

springs, in the order shown in

Fig. 53. Fig. 54 shows the rocker arm and shaft assemblies correctly installed on the

head.

The rocker

arm shafts are hollow and have holes drilled in them to allow oil to pass into

the rocker arms where they bear on the

shafts. |

|||

|

Fig. 51-Valve Lifters

When

assembling the valve lifter to the engine, it should be a free fit, and the end that

contacts the camshaft should be

smooth. If this surface shows signs of wear or roughness it is good

practice to replace the lifter.

The push

rods arc made from a solid piece of steel with the two ends forged to form

the contacts with the lifter and

rocker arm adjusting screw.

These ends are carefully machined and hardened to produce a smooth hard surface

that will give thousands of

miles of service with the minimum amount of

wear. |

|||

|

|

|||