1942 - 1947 CHEVROLET SHOP MANUAL

Section 7 - Transmission

|

|

|||

|

7-20 |

|||

|

|

|||

|

top holes

support the transmission during this operation and prevent damage to the clutch

disc.

6. Remove the transmission and

place it in the

transmission bench

stand.

DISASSEMBLY OF THE

TRANSMISSION (1/2, 3/4 and 3/4-Ton Special Trucks)

1. Mount transmission in holding

fixture.

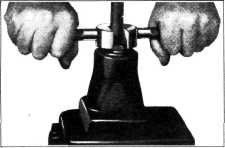

2. To remove the gearshift lever, slide the

open side of the K-353 gearshift lever remover and replacer over the

lever, engage the lugs of the tool in the open slot of the retainer, Fig.

34. Then press down on the tool and turn it to the left to disengage the

lugs on the retainer. Lift the

lever out of the cover. |

9. The

bearings can be removed from the main shaft and from the clutch gear by

supporting the inner race of each

bearing on an arbor press and

pressing on the end of the shaft until it is free of the

bearing.

Fig. 35 is a layout of the

four-speed transmission parts. This figure shows the back end construction

for Hotchkiss drive (items 31, 32 and

33) as used on the 3/4-ton long Wheelbase panel and all

1-1/2-ton trucks including

Cab-Over-Engine models.

INSPECTION

After the transmission has been

completely disassembled all

parts should be thoroughly washed in clean gasoline or cleaning

solvent and inspected for wear or damage.

All bearings should be thoroughly

cleaned, oiled with light engine oil,

and checked for scored races or worn balls or rollers. To check the

bearings for excessive looseness or for roughness, hold the inner race in one hand and turn the outer race

slowly in the other hand. DO

NOT spin bearing with compressed air.

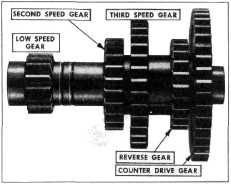

COUNTERSHAFT AND IDLER GEARS

Should it

be necessary to replace the gears on the countershaft, the old gears should be

pressed off on an arbor press

and the new gears pressed on the shaft. When reassembling the gears to the

countershaft, care must be used

to place the gears in correct position on the shaft and also to install

the three spacers in their

proper place between the gears.

The chamfered side of the second-speed gear faces the low-speed gear. The chamfered

side of the third-speed gear faces the chamfered side of the reverse gear. The illustration, Fig.

36. shows the order in which the gears are pressed on the shaft. |

||

|

|||

|

Fig. 34—Removing Gearshift Lever

3. Remove the transmission cover assembly and

place the transmission in two gears at once to lock the shafts.

4. Remove the speedometer driven gear and shaft

and with a long shank wrench remove the capscrew holding the universal joint to the

rear end of the transmission

main shaft. Remove the

universal joint; then remove the capscrews holding the rear bearing retainer and

remove the retainer from the

transmission case.

5. Remove the clutch gear bearing retainer and

drive out the clutch gear and

bearing, using a soft steel

drift to avoid damaging the teeth of the gear.

6. Remove the main shaft pilot bearing and

drive out the main shaft and

bearing through the rear end of

the case. Remove the sliding gears.

7. Drive out the reverse gear idler shaft from

the front to the rear

and remove the reverse idler gear.

8. Drive the countergear to the rear to remove

the rear bearing and its

retainer. Remove the countergear and drive out the countershaft

front bearing and retainer by

tapping lightly around the

outer race of the bearing. |

|||

|

|||

|

36.—Countershaft and Gears |

|||

|

|

|||