ROCHESTER CARBURETORS

Bulletin 9C-300 1 April 1953

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

INSTALLATION INSTRUCTIONS

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1. For

1932-1936 Replacement. (216 and 235 Cu. In.

Engines, l-1/4" S.A.E. Flange).

Remove old flange gasket. New asbestos flange gasket No. 839632 1/8"

thick must be used between

carburetor and engine manifold.

Bend accelerator throttle rod at

ends sufficiently before

attaching to carburetor throttle lever to provide necessary

clearance and to permit smooth operation and

travel of carburetor throttle

lever.

2. For

1937-1952 Replacement. (216 and 235 Cu. In.

Engines, l-1/4" S.A.E. Flange).

Install new flange gasket

No. 839632 1/8" thick on top of old heat insulator. This

|

3.

|

insures proper

operation of vacuum operated power system.

For 1950-52

Replacement (235 Cu. In. Truck Engines with 1-1/2" S.A.E. flange).

Moulded heat insulator No. 3692799 V2" thick must be used

between carburetor and engine manifold. This insures proper operation

of vacuum operated power system.

For 1950-1952

Replacement. (235 Cu. In. Powerglide Engines with 1-1/2" S.A.E.

Flange). Moulded heat insulator No. 3692799 V2" thick must be

used between carburetor and engine manifold. This insures proper

operation of vacuum operated power system.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

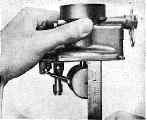

FLOAT LEVEL ADJUSTMENT

With air horn fully assembled, air

horn gasket in position and

assembly up-ended on a

flat surface (Figure 1):

1.

Place float level gauge in

position with gauge tang

inserted in discharge

nozzle.

2. Bend

float arms vertically so that

each float just touches top

portion of gauge.

3. Carefully

bend float arms horizontally

so that each float is centered

in the gauge.

4. Tilt

assembly 90° each side and check that floats do not touch

gauge.

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

FIGURE 1

|

FIGURE 2

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

FLOAT DROP ADJUSTMENT

As

shown in Figure 2, with the air horn held right side up and floats

suspended freely, bend the float tang at the rear

of the float

assembly so that the bottom of the float is 1-3/4" below the gasket

surface.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

THROTTLE RETURN CHECK

INSTRUCTIONS

1. Completely

assemble carburetor on engine manifold. Be certain accelerator pull

back spring No. 3695705 is

used.

2. If

necessary, bend the throttle return check bracket or throttle lever

contact arm to center the

adjusting screw on the radius of the contact arm.

3. Run the engine until it is warmed up.

4. Adjust

the throttle stop screw and idle adjusting needle to secure a smooth

idle at 500 R.P.M. in "N"

position.

5. Shut

off engine. Insert .090" feeler gauge between carburetor choke lever

cam and fast idle lever.

(Figure 3.)

6.

Using a 3/8" wrench turn the

adjusting screw until it just contacts the throttle

lever contact arm. Hold flats on

shaft with wrench whenever adjusting screw

is turned.

7.

Install air cleaner.

Start engine and recheck idling adjustment.

Float level gauge

M-250 is available from Borroughs Tool Company, Kalamazoo, Michigan

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

FIGURE 3

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

CARBURETOR SPECIFICATIONS

|

TUNE-UP SPECIFICATIONS

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

DIMENSIONS:

Primary Venturi—1-11/32" (.2350

cu. in. engines) 1-7/32"

(216 cu. in. engines)

Secondary Venturi — 19/32" (235 cu. in.

engines) 9/16" (216 cu. in. engines)

|

**lDLE DISCHARGE HOLES:

Idle Needle Orifice —.063

(1374, 2050, 3152, 3863,

3865), .067 {2051, 3060, 3160,

3864), .073 (4476, 3986,

4495), .081, (4475,

4477).

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

IDENTIFICATION:

Main Metering Jet—Stamped with last two

digits of Jet Part No.

Air Horn Gasket—Stamped

with last 4 digits of Gasket

Part No.

|

Second Idle Hole— .031

(2051, 3060, 3160, 3864,)

.034 (1374, 2050, 3152,

3863), .040 (3986, 4476,

4495),

.059, (4475, 4477).

Third Idle Hole—.028 (3986,

4476, 4495), .031 (1374,

2050, 3152, 3863, 3865),

.036,

(4475, 4477).

Fourth Idle Hole — .028

(1374, 2050, 3152, 3863,

3865).

Spark Hole —2 x .040

(all),

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

PUMP DISCHARGE HOLES:

.031 (235 cu. in. engines) .028 (216 cu.

in. engines)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

**POWER RESTRICTION:

.030 (1374), .038

(2050, 3152, 3863, 3865), .040 (2051, 3864), .041 (3060, 3160), .0375

(4475 4477), .046 (3986, 4495) .048 (4476).

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

**refers to carburetors which

have these digits as the last

four in its Part No. The first

three digits of each carburetor

number are 700.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

*Powerglide idling R.P.M. should be 500 in "N"

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

A GENERAL MOTORS PRODUCT

|

|

A UNITED MOTORS LINE

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||