ROCHESTER CARBURETORS

Bulletin 9C-301 1 April 1953

|

|

|||

|

CHEVROLET-1932-52

Automatic Choke Carb. for 216 Cu. In. Engine CARBURETOR

7004620-SERVICE PKG. 7005060

INSTALLATION

INSTRUCTIONS

1.

For 1932-1936 Replacement (216 Cu. In. Engines, 1-1/4" S.A.E.

Flange), Remove Old Flange

Gasket. New Asbestos Flange Gasket

No. 839632 1/8" thick must

be used between Carburetor and Engine

Manifold.

2. For

1937-1952 Replacement (216 Cu. In. Engines, 1-1/4" Engine

S.A.E. Flange), Install

New Flange Gasket No. 839632

1/8" thick

on top of old Heat Insulator. This

insures proper operation of

Vacuum Operated

Power Systems.

|

|||

|

|

|||

|

CARBURETOR ADJUSTMENTS

Make adjustments in following order—

|

|||

|

|

|||

|

|

||

|

|

|||

|

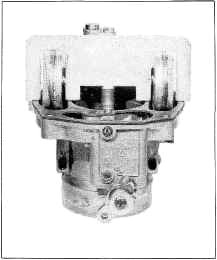

FIGURE 1

FLOAT LEVEL

ADJUSTMENT

With

air horn fully assembled, gasket in position

and assembly

up-ended on a flat surface (Figure 1);

1. Place

float level gauge in position with gauge

tang inserted in

discharge nozzle.

2.

Bend float arms vertically so

that each float just

touches top

portion of gauge.

3.

Bend float arms horizontally so

that each float is

centered in gauge.

4.

Tilt

assembly 90 degrees each side and check that

floats do not touch gauge.

|

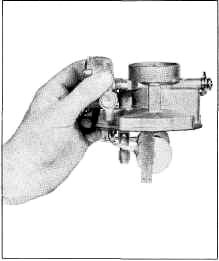

FIGURE 2

FLOAT DROP

ADJUSTMENT

As shown in Figure 2, to insure sufficient entry of

fuel under high speed operation,

it is necessary to check

and adjust the float drop. With air horn held right side up and floats

suspended freely, carefully

bend the float tang at the rear of

the float assembly so that

the bottom of the float is 1-3/4" below the gasket surface.

Install air horn assembly to float

bowl and tighten

screws evenly and securely.

|

||

|

|

|||