ROCHESTER CARBURETORS

Bulletin 9D-7 August, 1951

|

Bulletin 9D-7 August. 1951 Model

"BB" Page 4

ROCHESTER PRODUCTS, DIVISION OF GENERAL MOTORS, ROCHESTER, NEW YORK position. By the use of the

vacuum operated power system in the new carburetor, these power mixtures

are readily available. This is due to the ability of the power valve to

function at any drop in manifold vacuum below approximately 7" Hg.,

regardless of the degree of throttle opening. In carburetors which

employ a mechanically operated power system, the throttle must be advanced

to almost full wide open position to obtain the power

mixtures.

For good initial acceleration and

to minimize hard starting in hot weather, the model "BB" unit employs a

vented type of pump plunger. When the engine is not operating, the rise in

heat from the engine manifold causes the fuel in the pump system to boil.

The increased pressure from this boiling in conventional units often times

forces the fuel from the pump system into the engine.

The new type carburetor has a

ball type check valve built into the plunger head. As a consequence,

any fuel boiling below the pump plunger, is automatically vented by the

ball check into the float bowl. This system always provides solid fuel in

the pump chamber for smooth acceleration under relatively high temperature

operation.

SERVICE FEATURES The Model "BB" Carburetor has been designed with simplicity of construction and maximum ease of service. Both the idle tubes and pump jets, being pressed into the air horn and bowl castings respectively at the factory, need never be replaced or serviced. In many instances the entire unit will not have to be removed from the engine. All of the main metering parts are in the air horn assembly. By simply removing the cover screws and disconnecting the heat tube, choke arm, and pump rod, it is possible to service or inspect the Floats, float valve assembly, main well support assembly, power valve assembly, and automatic choke assembly. With the exception of the initial idle adjustment the model "BB" carburetor does not require any part throttle or power mixture adjustments. Since carburetion is dependent upon both compression and ignition, the carburetor should always be adjusted last in engine tune-up. |

|

|

|

|

|

IDLE SYSTEM

At small throttle openings, the

vacuum created at the main discharge nozzles is not great enough to cause

fuel to flow out of the nozzles. Therefore, an additional system has

been introduced to provide the relatively rich mixture ratios required

throughout the idling range.

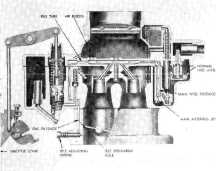

As shown in Figure 2, the idle

fuel first passes from the bowl through the calibrated main metering jets

in the bottom of the main well support assembly. The fuel is then drawn up

the main well by manifold vacuum to the Air Horn crossbar. Air is

bled |

|

|

MODEL "BB" IDLE SYSTEM Figure 2 |

|

|

|

|

|

into the solid fuel at the

calibrated air bleeds above the nozzles. This fuel/air mixture then passes

through the calibrated idle tube, (additional air entering thru the

crossbar idle air bleeds) and passes down the passage in the Float Bowl to

the Throttle Body. |

|

|

|

|