ROCHESTER CARBURETORS

Bulletin 9D-7 August, 1951

|

Bulletin 9D-7 August, 1951 Model "BB" Page 11

ROCHESTER PRODUCTS, DIVISION OF GENERAL MOTORS, ROCHESTER, NEW YORK

7. If wear is noted on steps of fast idle cam,

it should be replaced as it may upset engine idle speed during the choking

period.

8. Inspect pump plunger leather. Replace

plunger if leather is damaged.

9. If gaskets appear hard or brittle, replace

to insure a proper seal.

10. Check to see that lower end of choke suction

tube is tight in seal in throttle body. If not, a new seal will have to be

installed after the carburetor has been completely

assembled.

11. Inspect suction tube nut packing. If

compressed or out of round, replace.

ASSEMBLY AND ADJUSTMENT

IMPORTANT; To prevent poor

economy due to fuel leakage all threaded parts must be installed tightly.

This applies especially to the strainer nut and float needle

seat.

THROTTLE BODY ASSEMBLY

1. Install idle screw in throttle

lever.

2. Screw Idle adjusting needles and springs

into throttle body until they are finger tight.

Back out screw 1-1/2 turns as a temporary

idle adjustment. Make final adjustment on engine.

3. Install fast idle cam and fast idle screw

to throttle lever.

4. Upend bowl, place throttle body gasket in

position and attach throttle body. Tighten screws evenly and securely.

NOTE: New choke suction tube

seal, if needed, will be installed after carburetor is completely

assembled.

(See Page

15.) |

|

|

|

|

|

BOWL ASSEMBLY

With bowl again in upright

position, drop small aluminum pump inlet ball into pump well hole and

replace pump return spring.

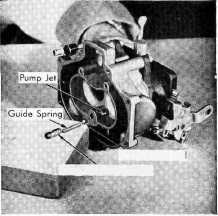

Install large steel ball in pump

discharge cavity. Place spring and pump discharge guide on top of ball.

(Figure 9) Press pump screen carefully into position.

AIR HORN ASSEMBLY

With Air Horn upended on a flat

surface,

install float needle seat and

gasket, using

screwdriver with a 1/2" bit.

Place small pump vent disc and retaining

clip into pump vent.

Place Power Piston spring and

Power

Piston into vacuum cavity. Piston

should

vide free in

cavity. |

Pump Outlet Ball Pump Discharge

Guide |

|

Figure 9 |

|

|

|

|