|

ROCHESTER CARBURETORS Bulletin 9D-9 January 1952 |

|||||

|

Page 7 ROCHESTER

PRODUCTS, DIVISION OF GENERAL

MOTORS, ROCHESTER, NEW YORK |

|||||

|

|

|||||

|

POWER SYSTEM

|

|||||

|

|

|||||

|

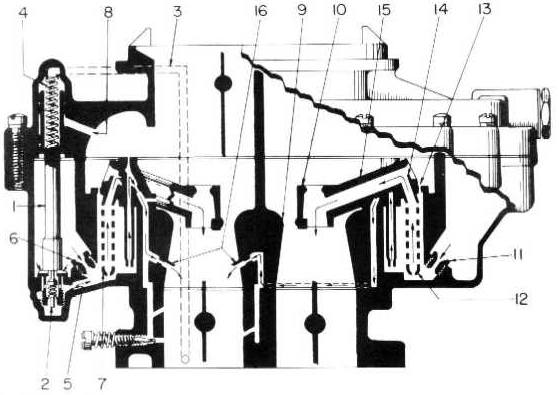

Figure 7-3 |

|||||

|

|

|||||

|

Use Figure 7-3 as a

reference.

To achieve the proper mixtures

required when more power is desirable or sustained high speed driving is

to be maintained the Model 4GC Carburetor employs the use of a vacuum

operated power piston (1) in the air horn and a power valve (2) in the

float bowl. This power system is located on the primary or pump side of

the carburetor.

The power piston vacuum channel

(3) is exposed to manifold

vacuum beneath the throttle valves. The vacuum in this channel varies

directly with the manifold vacuum. In the idling and part throttle

ranges, the manifold vacuum is normally quite high. This vacuum is

sufficient to hold the power piston (1) in its extreme up position.

However, as the throttle valves are progressively opened the manifold

vacuum drops. When the vacuum drops below approximately 7" Hg. the

calibrated spring (4) beneath the power piston forces the piston

down. This situation occurs at very high driving speeds or on rapid

accelerations. When the piston drops down, it unseats the spring loaded

power valve (2). This permits additional fuel to flow from the float bowl

through the calibrated power restrictions (5) and into the main wells. 1

his additional fuel supplements that already flowing through the main

metering jets (6) and main well tubes (7), (on the Primary side) thus

making the mixture being delivered to the manifold, consider-ably richer

than normal Part Throttle mixtures. This power mixture continues to be

supplied as long as the manifold vacuum remains below approximately 7" Hg.

When the manifold vacuum again increases sufficient-ly, the force of the

power piston spring (4) is overcome and the piston is drawn up, thus

returning the carburetor |

to the economical part

throttle mixtures.

It will be noted that the power

piston cavity in the carburetor air horn is connected to the main air flow

passage by a vacuum break hole (8). It is the purpose of this hole to

prevent the transfer of vacuum acting on the piston from acting also on

the top of the fuel in the float bowl. Any leakage of air past the upper

grooves of the piston will be compensated for by this vacuum break hole

and will not affect carburetor calibration.

It is also in this range that the

secondary side of the carburetor provides additional air and fuel to the

engine for increased power. For high speed operation, beyond the part

throttle range, the throttle linkages engage the secondary throttle valves

and open them completely in the remaining few degrees of primary throttle

travel.

In this range manifold vacuum or

suction, acting on the secondary side of the carburetor is multiplied at

the primary (9) and secondary (10) Venturi and draws fuel from the

float bowl through the calibrated main metering jets (11) into the main wells. This fuel

then passes through the main well tubes (12) and is bled in a manner similar

to that discussed previously in the operation of the Primary main well air

bleeds. This mixture is bled further at the main well bleeds (13) and is then drawn to the tips

of the main well tubes (14). It then passes through the mixture passage

(15) to the secondary Venturi

(10) and is discharged into the intake manifold.

The lower idle air bleeds (16) also supply fuel throughout the

power range in a manner similar to that discussed under the Part Throttle

System operation. |

||||

|

|

|||||