ROCHESTER CARBURETORS

Bulletin 9D-7 August, 1951

|

Bulletin 9D-7 August, 1951 Model

"BB"

Page 6 |

|

|

|

|

|

ROCHESTER PRODUCTS, DIVISION OF GENERAL MOTORS, ROCHESTER, NEW YORK |

|

|

|

|

|

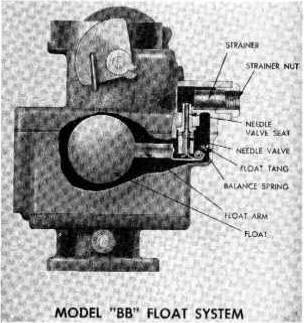

FLOAT SYSTEM To aid in maintaining the correct fuel level under all conditions the carburetor employs twin floats. It is of the utmost importance that the floats be adjusted carefully and accurately. (See Figure 5)

SEE ADJUSTMENT BULLETIN FOR CORRECT FLOAT SETTING. |

|

|

ACCELERATING PUMP SYSTEM When the throttle is opened suddenly the air flow and manifold vacuum change almost instanteously, while the heavier fuel tends to lag behind causing a momentary leanness. The accelerator pump provides the additional fuel necessary for smooth operation on rapid acceleration. (See Figure 6) |

|

|

MODEL "BB" FLOAT SYSTEM

Figure 5 |

|

|

|

|

|

A double spring pump plunger is

used on the model "BB" carburetor. The rates of compression of the

top spring versus the bottom spring are calibrated to insure a smooth,

sustained charge of fuel for acceleration.

On the pump intake stroke, fuel

passes through the pump inlet screen, unseats the inlet ball, and fills

the pump well.

The accelerator pump, being

connected directly to the

throttle, moves at the slightest change in throttle opening. The

force of the pump plunger upon acceleration seats the inlet ball, forces

fuel through the outlet channel which unseats the spring loaded outlet

ball and then discharges through the pump jets, into the main air

stream.

NO TARGETING OF THE PUMP JETS IS REQUIRED.

MODEL "BB" PUMP SYSTEM

Figure 6

|

|

|

|

|