|

ROCHESTER CARBURETORS Bulletin 9D-8 August, 1951 |

|||

|

Bulletin 9D-S

August. 1951

Model "BC"

Page 7

ROCHESTER PRODUCTS, DIVISION OF GENERAL MOTORS.

ROCHESTER, NEW YORK

The pump plunger head has been

designed to eliminate fuel percolation in the pump system. This has been

accomplished by the unique design of a ball check and seat in the plunger

head. When the engine is not operating, any build up of fuel vapors in the

pump well rise and by-pass the ball. This allows the hot fuel and vapors

to circulate up the passage in the plunger head and return to the float

bowl. Without this feature, any vapor pressure built up would evacuate the

fuel in the pump system into the engine manifold, causing poor initial

acceleration due to lack of fuel in the pump system as well as difficult

hot weather starting. |

|||

|

|

|||

|

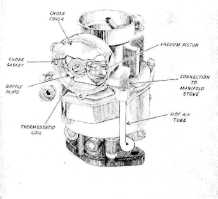

CHOKE SYSTEM

To insure proper starting and

driving during cold weather operation, the Model "BC" Carburetor

employs a fully automatic choke. (As shown in Figure 7.) This choke system

is composed of a thermostatic coil, choke piston, choke valve and fast

idle cam and linkage. It is controlled by a combination of intake manifold

vacuum, the offset choke valve, atmospheric temperature, and exhaust

manifold heat.

The thermostatic coil, which is

linked to the choke valve shaft, holds the choke valve closed when the

engine is cold. As the engine is started, air velocity against the

offset choke valve causes the valve to open slightly against the torque of

the thermostatic coil. In addition, as the engine starts, intake

manifold vacuum is applied to the choke piston. which also tends to

pull the choke valve open. |

||

|

Figure 7. Choke System |

|||

|

|

|||

|

As a consequence, the choke valve

assumes a position where the torque of the thermostatic coil is balanced

against the vacuum pull upon the choke piston and air velocity against the

offset choke valve, thereby causing a regulated air flow into the

carburetor which provides a proper mixture during the warm-up

period.

During warm-up, the choke piston

serves to modify the choking action to compensate for varying engine loads

or acceleration. Any acceleration or increased road load decreases the

vacuum exerted on the choke piston. This allows the thermostatic coil

torque to momentarily increase choke valve closure to provide the engine

with a sufficiently richer mixture for acceleration.

As the engine warms up, hot air

from the exhaust manifold "stove" is drawn into the ther-mostatic coil

cover by the vacuum behind the choke piston. This hot air causes a rise in

temperature which causes the coil to slowly relax its tension. Thus the

choke valve is allowed to move gradually to the full open

position. |

|||

|

|

|||