1942 - 1947 CHEVROLET SHOP MANUAL

Section 1 Body

|

|

|||

|

1-1

|

|||

|

|

|||

|

Section I

BODY

(PASSENGER CAR)

|

|||

|

|

|||

|

CONSTRUCTION

|

and nuts in the lower part of the windshield opening

and at each hinge pillar.

The side roof rails

are all steel box section con-

|

||

|

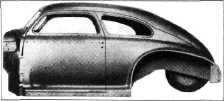

The Fisher Unisteel Turret Top Body is built up

from five major panel

assemblies-Namely: the

floor, cowl and dash, right and left rear quarter

panels, and the roof. These steel

panels are welded together

to form the shell of the complete body

unit.

The following figures,

1 and 2, show the location of the

welding lines for the Fleetmaster and Stylemaster sedan and sport

sedan, and the Fleetline Aerosedan.

|

|||

|

|||

|

|||

|

Fig. 1- Location of

Welding Lines (Fleetmaster and Stylemaster Sedan and Sport Sedan)

|

|||

|

|||

|

Fig. 2-Location of Welding Lines (Fleetline

Aerosedan)

In addition to the welding lines shown in figures

1 and 2, the roof panel is welded

to the top of the front

body hinge pillar cover panels, which are a

part of the cowl and dash

assembly. The quarter

panels are spot-welded to the wheel housing as

shown in figures 1 and 2. The

upper part of the quarter panels is spot-welded to the roof

panel.

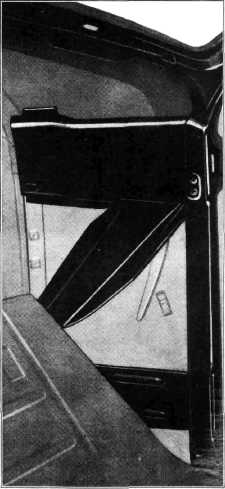

The cowl and dash assembly is strengthened by bracing. It will be

noted in Fig. 3 that three braces

are welded to the front body hinge pillar. This makes an extremely

rigid mounting for the door.

The instrument panel is a separate stamping

attached to the cowl and dash

assembly by screws

|

|||

|

Fig. 3-Cowl and Dash Assembly Bracing

|

|||

|

|

|||