1942 - 1947 CHEVROLET SHOP MANUAL

Section 1 Body

|

|

|||

|

1-14

|

|||

|

|

|||

|

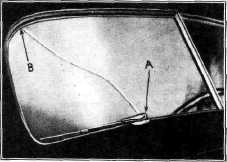

present. Examine the opening at the point

where the glass cracked (See A and

B Fig. 28) and remove, or

correct any obstruction or high

spot that may be found. It may be

necessary to peen the

windshield flange or it may be that

the weld at the upper corner of

the windshield opening is protruding too far. It is also possible

that the windshield wiper

housing cap shown at "A"

in Fig. 28 may be tightened in such a

manner that it binds on the

windshield glass. The cut-out on the top of the cowl for the

windshield wiper mechanism may

also be exerting too much

tension against the glass. The

cause, whatever it may be, of the

windshield glass cracking

should be removed before a new

glass is installed.

5. Using

FS-638 sealing compound lay a 3/16" bead

of this compound on the inside

lower edge of the pinch

weld rubber channel entirely around

the glass opening as shown in the

left-hand picture in Fig.

29.

6. Insert

the new glass into the windshield rubber

weatherstrip and work the rubber

on to the glass. Push

glass and rubber molding into the

windshield opening. Before

starting this operation,

make sure all old sealing compound is

cleaned out of the windshield

rubber weatherstrip and in

the vicinity of the lower center

division of this weatherstrip.

7. Re-install

the windshield garnish molding,

pressing firmly to position. Finish at the top and bottom

centers by replacing medallions

over center joints.

8. Set

all the garnish molding screws tight and

remove masking tape from

instrument panel.

9. On

the outside of the windshield as an added precaution, the lip of the

rubber weatherstrip

against the glass should be cemented to the glass using FS-655 rubber

cement in the B-182-A body

cement gun. Cement all around the

glass. Any excess cement should

be removed using oleum

spirits sparingly.

|

Windshield Sealing

(Fleetline and Fleetmaster Models)

On these models a rubber channel fits over the

pinch weld around the windshield

opening. This channel which

is separate from the glass channel has a center section which

laps around the center division

channel. The cross section in Fig. 29 shows the assembly

details. The inner side of this rubber

laps back, forming a slot for the

rear flange of the plated

windshield reveal molding.

When installing this

rubber seal, the pinch weld and

the center division channel should be coated with FS-655 rubber

cement.

The chrome-plated center division channel cap

molding must be installed before

installing the windshield.

When installing a windshield, lay a bead of FS-638

sealing compound at the intersection of the pinch weld rubber channel

and the windshield opening at the rear side; also load the full

length of

|

||

|

|||

|

Fig. 29-Fleetmaster Windshield and Reveal

Molding Seal

the slot between the

end of the rubber on the center division channel.

Using a B-182-A body cement gun, lay a bead

of FS-655 rubber cement in the

glass groove of the

windshield rubber; then install the windshield glass

or glasses in the rubber channel.

The assembly can then be pressed into the opening.

NOTE—Should it

become necessary to remove the center division channel cap molding, it

is necessary to loosen the garnish molding first; otherwise the

molding will be damaged.

Windshield Sealing

(Stylemaster Model)

The windshield on this model, which does not

have the plated reveal moldings as

on the Fleetmaster model,

is sealed as follows: 1.

On the outside of the windshield opening, work

or straighten up the lip of the

rubber weatherstrip, so

that it lies in correct position against

the glass. It may be necessary to

loosen the

|

|||

|

|||

|

Fig. 28-Points of Possible Obstruction in

Windshield Opening

|

|||

|

|

|||