1942 - 1947 CHEVROLET SHOP MANUAL

Section 12 - Electrical System

|

|

|||

|

12-27

|

|||

|

|

|||

|

Reassembly

1. Assemble

the governor weights over their pivot

pins. Lubricate the top end of

the shaft with light

engine oil and install the cam.

2. Assemble

the advance mechanism cover. Install

the two lock plates and nuts.

After tightening the nuts

securely, lock them by bending up the

tangs on the lock plates.

|

ADJUSTING BREAKER POINTS

The contact points on the distributor are fixed

in their mounting and are

controlled by an eccentric

screw moving the mounting plate. To adjust

the gap of these points, proceed

as follows: Remove the

distributor cap and rotor. Hand crank

the engine until the breaker arm

rubbing block is on the

peak of the cam. The contact points are

then opened the maximum distance.

Loosen the lock screw and

turn the eccentric adjusting screw,

as shown in Fig. 57, to the right

or left, increasing or

decreasing the gap to .018". Tighten the lock

screw.

|

||

|

|||

|

|||

|

Fig. 57-Adjusting Distributor Breaker Points

When installing new points it is advisable to

set the gap at .020" to .022" to

compensate for initial wear

on the fiber rubbing block while breaking in.

COIL

The ignition coil is rilled with transformer oil

and is hermetically sealed to

prevent the entrance of

moisture. A large porcelain insulator is used at

the secondary terminal to provide

effective insulation.

Coil tests can only be made on coil test equipment;

therefore, the instructions of the equipment

manufacturer should be followed.

REVERSING SWITCH

A switch mounted on top of the starting motor,

as shown in Fig. 58, and operated

by a connecting lever to

the starter drive shift lever, is used to reverse

the direction of the current flowing through

the ignition primary circuit to

the breaker points in the

distributor each time the engine is started,

without changing the polarity of

the secondary circuit.

|

|||

|

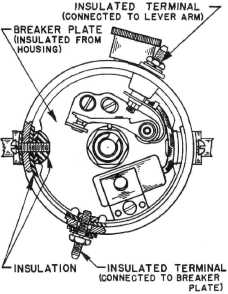

Fig. 56-Ignition Distributor Connections

3. Lubricate

the shaft and install it in the distributor

housing. Install the drive gear and pin.

4. Install

the breaker plate in the distributor body,

assemble breaker plate

insulation. Then assemble

the distributor cap retaining clips; the

screws which mount the clips are

screwed into insulation

nuts on the inside of the breaker

plate, Fig. 56.

5. Install

the primary terminal insulation bushing

in the housing. Thread the

terminal through the

bushing and install the insulation washer,

flat washer, lockwasher and nut.

6. Assemble

the condenser to the breaker plate,

making sure the connections are

clean.

7. Install

the distributor points and set the gap at

.018".

8. Install

the bakelite shaft contact plug, spring

and grease cup.

|

|||

|

|

|||