1942 - 1947 CHEVROLET SHOP MANUAL

Section 12 - Electrical System

|

|

|||

|

12-29

|

|||

|

|

|||

|

If the above conditions do not prevail and current

does not pass through the reversing switch,

check the operating link and

over-travel spring for

proper assembly. If assembly is correct and trouble

still exists, replace switch.

SPARK PLUGS

The spark plugs are 10 millimeter AC-104. The

gap setting is .040". Care must

be used when installing

spark plugs to prevent upsetting the gaps

by overtightening the plugs. When

installing spark plugs,

use new gaskets and screw each plug in

finger tight, then tighten with a

wrench 1/2 to 3/4

turn beyond finger tight. If used gaskets are being

reinstalled, screw each plug in finger tight, then

tighten with a wrench 1/8

to 1/4 turn beyond finger tight.

If a tension wrench is used, the plugs should not

be tightened over 15 foot pounds

maximum.

The two important things to remember about

spark plugs are that they be kept

clean and that the gap

between the electrodes is properly adjusted. The gap should be

checked with a round feeler

gauge and set at .040".

Spark plugs have much more to do with the performance

and economy of engines than is generally

recognized.

With high combustion chamber temperatures

and the modern anti-knock fuels,

spark plugs require much

more attention because of the tendency

for oxides to deposit on the

porcelain.

This oxide is a fine, white, powdery substance which becomes impinged

upon the insulator, usually accumulating far up in the shell, but is

also deposited upon the insulator

tip.

This coating, being dry, is easily removed and

it is better to remove it when it

first forms, so that it

will not have an opportunity to accumulate and

melt into a glaze. Spark plug

cleaning, in an abrasive,

air-blast type cleaner, every 3,000 to 4,000

miles, will take care of it.

Under higher

temperatures, the white oxide becomes

fused or melted by combustion heat and

forms a smooth, glassy coating

over the insulator. An insulator in this degree of oxidation

presents the appearance of having

been coated with a heavy machine oil. It is light yellow in

color, with a hard, shiny glaze. A plug in this condition will often

perform satisfactorily when

cool, but will miss badly as soon as it becomes warmed up.

Fused oxide coating is very deceiving. Even

after an apparently thorough

cleaning, there is apt to

remain on the insulator a practically invisible

layer of oxide. The plug looks

clean, but really isn't.

The safest way to handle such plugs is to

clean them until you are

absolutely sure that they

|

are clean and then start all over and clean them

again. This coating is difficult

to remove and only a

double dose of cleaning can insure satisfactory

performance.

If spark plugs are allowed to go for 8,000 to

10,000 miles without cleaning,

the oxides will form into

blisters and the only remedy for this condition

is replacement of the plugs.

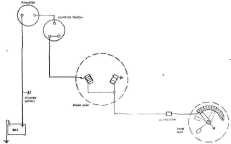

THE GASOLINE GAUGE

The gasoline gauge is composed of two units,

the indicating or dash unit

mounted on the instrument panel and the tank unit mounted in the

gasoline tank. The circuit

for this instrument passes through the ignition switch, therefore the

gasoline gauge operates

only when the ignition switch is

"on."

OPERATION

When the gasoline tank is empty, current flows

from the battery positive through

the ammeter to the

ignition switch and then to the gasoline gauge

dash unit top terminal. The

current now passes through the choke or limiting coil to the

common connection between the two

coils, which is the lower terminal on the dash unit. At this

point the current is offered two paths, one through the operating

coil of the dash unit and the other over the wire to the tank unit.

When the gasoline tank is

empty, the contact finger of the tank unit cuts out all the resistance

in the tank unit. The largest pro-

|

||

|

|||

|

Fig. 61- Gasoline Gauge Circuits

|

|||

|

portion of the current will pass through the tank

unit circuit and only a very

small portion through the

operating coil of the dash unit, with the result

that there is not sufficient

current being forced

through this operating coil to move the hand in

the dash unit. If the gasoline

tank is half full, the

cork float of the tank unit rises on the gasoline

and moves the contact finger over

the resistance, cutting

resistance into the tank unit circuit as indicated by the lines in

Fig. 61.

|

|||

|

|

|||