1942 - 1947 CHEVROLET SHOP MANUAL

Section 4 - Rear Axle, Universal Joints & Springs

|

|

||||

|

4-7 |

||||

|

|

||||

|

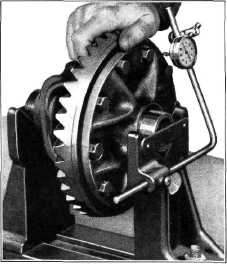

2. Place

the differential case in the "V" blocks of the checking fixture U-4 and indicate

the run-out of both the ring

gear pilot and the case flange,

Fig. 10. Neither of these run-outs should exceed

.001". |

flush with the face of the case.

Remove the guide pins and install the

remaining bolts. |

|||

|

Tighten all ring gear

bolts.

NOTE—New lockwashers should

under the head of each bolt. |

be used |

|||

|

||||

|

With the

assembly mounted in "V" blocks, check

the run-out of the back face of the ring gear with a dial indicator. Fig. 12. This

runout must not exceed

.004". |

||||

|

||||

|

Fig. 10—Checking Run-Out of Differential

Case

When

replacing the ring gear, it is good practice to use five guide pins made by cutting

the heads from 3/8"—24 cap

screws about 1-1/2" long. Slots should be cut in the heads of these

guide pins so that they may be

easily removed. Install

these guide pins in alternate bolt holes in the ring gear, Fig. 11, and slip the ring

gear over the pilot diameter of

the case, making sure |

||||

|

Fig. 12—Checking Run-Out of Back Face of Ring

Gear

Assembling the Rear Axle

1. Assemble the same thickness of shims in the

counterbore of the propeller

shaft housing that were removed

when the assembly was taken down (if the original ring gear and pinion are

to be used), making sure that

the shims are flat in the

counterbore and are not cocked. The total thickness of the shims will be found

to be from .030" to .036" and

usually .033". Shims are

serviced in thicknesses of .012", .015", .018", and .021" so that a combination of

shims may be selected to

replace the original ones if they are damaged.

NOTE—Whenever a new ring gear

and pinion is installed, one .015" shim and one .018" shim should be used

as this is the standard setup.

2. Coat the beveled surface of the pinion

bearing lock sleeve with rear

axle lubricant, and as- |

||||

|

||||

|

Fig. 11—Use of Guide Pins in Ring

Gear

that the

back face of the ring gear and the face of the case are free from dirt and burrs.

Install every other ring gear

bolt and draw them up evenly

and snugly so that the ring gear face is |

||||

|

|

||||