1942 - 1947 CHEVROLET SHOP MANUAL

Section 4 - Rear Axle, Universal Joints & Springs

|

|

|||

|

4-18 |

|||

|

|

|||

|

On the

double reduction shaft are the two double reduction pinions, each of which has an

integral spur pinion on its

inner side. Between them are two sets of short splines integral with the

shaft, and a floating shifter

sleeve that is moved by a shifter mechanism to lock one set of splines

on the double reduction shaft

with the spur pinion on one or

the other double reduction pinions.

The control is operated by a lever

in the cab and connected to the

shifter lever on the axle by cable and rod linkage. As the shifter

lever in the cab is moved to the

forward position, the shifter sleeve is moved to the right, locking

the double reduction high-speed

pinion to the double reduction shaft, at the same time disengaging the double

reduction low-speed pinion, permitting it to turn freely on the

shaft. The power from the engine is

then transmitted through

the propeller shaft, pinion and ring gear, then to the double reduction

shaft and high-speed pinion.

Thence to the high-speed double reduction gear through the

differential to the rear axle

and wheels, Fig. 33. |

screws

alternately, the axle shafts and aluminum gaskets can be removed from the wheel hub,

Fig. 34.

Remove the

capscrews which fasten the differential carrier to the axle housing

and place a jack under the carrier.

The assembly can now be removed from under the

truck. |

||

|

|||

|

|||

|

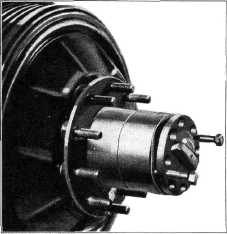

Fig. 34—Axle Shaft Removal

Differential and Carrier Disassembly

Place the

assembly in a bench vise by clamping on the lower rib of the carrier. Remove the

cotter pin, nut and washer

from the end of the pinion shaft. The universal joint yoke may then be

removed from the shaft.

Before

removing the differential assembly from the carrier, mark the differential bearing

caps and adjusting nuts with a center punch for position identification when reassembling. This is

important because the caps are machined in place.

Remove the tie wire, differential

bearing adjusting nut locks and

the bolts from the bearing caps. Remove the bearing caps and

differential assembly from the

carrier.

To remove

the pinion cage and bearing assembly, remove the nuts which retain the cage

to the carrier.

NOTE—There are two tapped holes

in the flange of the cage for use when removing a tight cage. It Is most

important when removing the pinion cage and the double reduction shaft

bearing caps that that number and thickness of the shims be checked for

reference when reassembling. This will save considerable time when making

adjustments. |

|||

|

Fig. 33—Two-Speed Axle Operation [High Gear)

When the

shifter lever is moved backwards the shifter sleeve is moved to the left,

disengaging the double

reduction high-speed pinion and transferring the power through the low-speed pinion

and low-speed gear to the rear

axle and wheels.

REPAIR OPERATIONS

Wheel hubs,

bearings, oil seals, and axle shafts are serviced in the same manner as on the

conventional 1-1/2-ton truck rear axle.

Removal of the Differential and Carrier

Remove the

two trunnion bearing "U" bolts from

the rear yoke. Split the universal joint, shift the propeller shaft forward and allow the

rear axle propeller shaft to drop down.

Remove the

capscrews and locks which retain the

axle shaft flange to the wheel hub.

Install two 7/16"-14 cap screws in

the holes provided in the shaft

flange and by turning the cap |

|||

|

|

|||