1942 - 1947 CHEVROLET SHOP MANUAL

Section 5 - Brakes

|

|

|||

|

5-4 |

|||

|

|

|||

|

by the

pistons to lubricate them, the glucose will form a sticky rim around the cylinders,

preventing piston

action.

The fourth

type, or mineral oil such as motor oil in shock absorber fluid, is the one to

guard against most strenuously.

Even slight traces of mineral

oil are enough to destroy the sealing qualities of the rubber cups in

two or three days. Cylinders and parts should never be washed in

gasoline, as even the small

amount of mineral oil present in gasoline will affect the rubber

seals.

The last

named type, or plain alcohols, most of which contain up to 10% water, should never

be used as the alcohol has no

lubricating properties at all and, due to its extreme thinness, will leak

past the rubber cups and saturate the brake linings.

In the

event that improper fluid has entered the system, it will be necessary

to—

1. Drain the entire

system.

2. Thoroughly and vigorously flush the

system with clean alcohol, 188

proof, or a hydraulic brake

system cleaning fluid known to the industry as "Declene."

3. Replace all rubber parts of the system

including brake

hoses.

4. Refill the system with G. M. Hydraulic Brake

Fluid, Super No.

9.

HYDRAULIC BRAKE TUBING

The

hydraulic brake tubing is a double layer flexible steel, copper-coated, tin-plated

tubing which resists corrosion and also stands up under the high pressures which are developed when

applying the brakes. |

The

important thing in connection with making up hydraulic brake pipes is the proper

flaring of the ends of the tubing for the compression couplings. Unless the tubing is properly flared

the couplings will leak and

the brake will become ineffective.

This

safety steel tubing must be double-lap flared at the ends in order to produce a

strong, leak-proof

joint.

The brake

tube flaring tool shown in Fig. 6 is used to form the double-lap

flare. |

||

|

|||

|

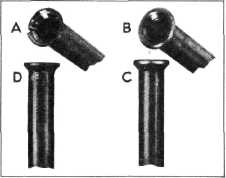

Fig. 7— Single and Double Lap Flare on Tubing

End

Fig. 7 shows two pieces of

tubing—one with a single-lap flare

("A") and the other with the double-flap flare ("B"). It will be noted

that the single-flap flare

split the tubing while the one shown in "B" has a heavy, well-formed

joint.

DIRECTIONS

1. Cut the

tubing to the desired length, using a tube cutter to prevent flattening the

tubing. Square off the end

with a fine-cut mill file, then ream the sharp edges with the reamer blade

provided on the tube cutter,

Fig. 8. |

|||

|

|||

|

|||

|

Fig. 8-Cutting Hydraulic Brake Tubing

2. Place new compression coupling

nuts on the tubing. Dip end of tubing

to be flared in hy- |

|||

|

Fig. 6-Hydraulic Brake Tubing Flaring

Tool |

|||

|

|

|||