1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

|||

|

6-5 |

|||

|

|

|||

|

5. Expand

the reamer by easy stages and repeat the reaming operation until the piston pin

is fitted.

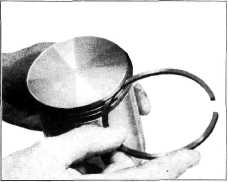

The proper

fit of the piston pin is a "thumb push" fit as shown in Fig.

6. |

tapered

one thousandth of an inch, being wider at the bottom. With this design the lower edge

of the ring tends to scrape the

excess oil from the cylinder wall and acts as an oil control ring until

the regular oil control ring

is seated (broken-in) in the cylinder. All compression rings

are marked with the word "TOP" cast

in the upper side of the ring. When installing compression rings, make sure

the side marked "Top" is

toward the top of the piston. Chevrolet piston rings are furnished in

standard sizes as well as

.005", .010", .015", .020", .030" and .040" oversizes.

Fitting Piston Rings

To

properly fit new piston rings, proceed as follows:

Slip the

ring into the cylinder then, using the head of a piston, press the ring into the

cylinder bore about two

inches. Using a piston in this way will place the ring square with the cylinder

walls. Now check the space, or

gap. between the ends of the

ring. This should be from .005" to .015".

If the

space between the ends of the ring is less than .005", remove the ring and try another

ring for fit, or the gap in the

tight fitting ring may be enlarged by the following method: Remove

the ring from the cylinder.

Clamp a fine-cut file in the vise. Grasping each end of the ring firmly

between thumb and fingers,

work the two ends of the ring across the surfaces of the file pressing the

ring together at the gap

lightly, until the proper space is obtained. Be careful not to distort the

ring during this operation or

it may bind in the ring groove of the piston. Fit each ring

separately. |

||

|

|||

|

Fig. 6—Fitting Piston Pin

After

fitting the first piston pin, the other bushings may be reamed

quickly by reducing the diameter

of the reamer by approximately .0005" (half a thousandth) by backing off the expansion

screw. This permits quick roughing-out of all bushings, leaving about half a thousandth for the

finish cut.

It is good

practice to check the diameter of all piston pins with a micrometer. In case

there should be a slight

variation in diameter, this must be taken into consideration when adjusting the

reamer for the finish cut.

The

purpose of the reaming fixture is to make sure that the piston pin bushings will be

reamed at right angles to the

skirt of the piston, assuring proper alignment of the piston in the

cylinder.

Chevrolet

piston pins are serviced in standard sizes as well as .003", .005", and .010"

oversizes.

PISTON RINGS

The

purpose of a piston ring is to take up the space between the cylinder walls and the

piston, to prevent leakage of

gases and oil.

As these

gases are under considerable pressure, it is therefore necessary that the rings

not only fit snugly around the

cylinder walls, but in the grooves of the pistons as well; otherwise

the gases and oil will work by

behind the rings.

The

compression piston ring used in the Chevrolet engine is designed to control oil

consumption during the break-in

period. The face of the ring is |

|||

|

|||

|

Fig. 7—Rolling Piston Ring in Ring Groove

New piston rings and cylinder

bores wear considerably during

seating and the gaps widen quickly. Engine operation will not

become seriously affected if ring

gaps do not become greater than 1/32". |

|||

|

|

|||