1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

|||

|

6-7 |

|||

|

|

|||

|

necessary to replace the clutch

housing, the new housing must be

assembled to the block and checked before main bearings are

installed. The housings furnished for service are selected and are interchangeable with the production

part.

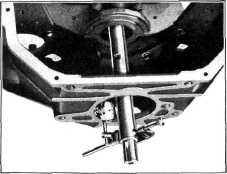

Main Bearing Boring Machine

This unit consists of the

following parts, Fig. 10.

A—Support

Bracket and Clamps

B—Universal Clamp

Bolts

C—Boring

Bar Supports and Ball Bearings

D—Boring Bar Centering

Bushings

E—Clutch Housing Centering

Bushing

F-Boring

Bar

G—Boring

Bar Feed Support Bracket

H-Feed Nut

Yoke

I—Feed Screw

J—Turning

Handle K—Boring Bar

Cutters

The

operations for replacing main bearings are as follows:

1st—Support the Crankcase in the

motor stand

with

bearing side of case up. 2nd—Remove

old bearings and see that case is

well cleaned.

3rd—Install centering

bushings "D" in the front and rear bearing bores and install the

bearing caps without

shims.

4th—Thread

the boring bar "F" through the bushings from the rear to the front. Then

mount the dial gauge on the

boring bar and check the

alignment of the transmission pilot hole in the clutch housing, Fig. 11.

The runout must not exceed

.015". If it does, it will be

necessary to replace the clutch

housing before proceeding with the installation of the new main

bearings. |

5th—Remove the boring bar and the

centering bushing from the rear

bearing. Then install the

clutch housing centering bushing "E" in the transmission pilot hole of the clutch

housing.

6th—Install

the boring bar through the rear centering bushing and thread the boring bar

support bearings "C" over the bar, locating one support in the space

between each two bearings. Be

sure to push the boring bar through the front centering bushing beyond

the reduced diameter portion.

7th—Install the boring bar support brackets "A" and line them up so there will be clearance

between the bearing cap and

support bracket for the

installation and removal of cutters. Clamp the support brackets firmly

to the oil pan rail of the

cylinder block. 8th—Tighten the

universal clamp bolts "B" on each support bracket evenly. As the

bolts are being tightened, the boring bar should be turned by hand to make sure that it is

free to turn without any

indication of a bind. Remove

the boring bar and the front centering bushing. 9th—Install the bearing shells in the

cylinder

block and

caps.

NOTE—The front and

front intermediate bearing shells are very similar in

appearance and it is possible to get them mixed. The front

intermediate shells are

identified by the letter "I" in the bottom of the oil groove. Should

the intermediate

bearing shell be installed in the front bearing bore, the sides of the

bearing would be too

high and would not permit the cap to seat firmly on the shims.

10th—Place four .002" shims

on each side of each bearing

and install the caps. The intermediate bearing caps are marked

"front" and "rear" for identification

purposes. The front

intermediate bearing cap is installed with the "FRONT" mark to the front of the

engine and the rear

intermediate bearing cap is

installed with the "REAR" mark to the rear of the engine.

The rear

intermediate bearing shell is flanged

because it takes the end thrust of the crankshaft.

Tighten the

bearing cap bolts evenly and make

sure they are drawn down tight. 11th-Examine the boring bar to make sure

the cutter scats are clean; then install the bar through the rear centering bushings and

bearing supports. Examine the

cutters to make sure they are

clean and install them in the

slots in the cutter bar. Cutters are lettered F-FC-RC-R to designate front,

front center, rear center, and

rear. |

||

|

|||

|

Fig. 11— Checking Transmission Pilot Hole in Clutch

Housing |

|||

|

|

|||