1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

|||

|

6-9

The

machining operations are performed on the most up-to-date machines obtainable. The

bearing surfaces are ground and polished to a mirror finish,

then rolled under heavy pressure to produce a hard, long wearing

surface.

The

crankshaft main bearing journal and connecting rod journal sizes are as

follows:—Front, 2.6835"-2.6845"; Front Intermediate,

2.7145"-1.7155"; Rear

Intermediate, 2.7455/'-2.7465"; Rear, 2.7765"-2.7775";

Connecting Rod Journal, 2.311"-2.312".

Whenever a

crankshaft has been removed from an

engine, it is important that these dimensions be checked with a micrometer for out-of-round,

taper and undersize. If the

journals exceed .001" out-of-round or taper, the crankshaft should be

replaced. Slightly undersize journals can be used providing that they are within the above limits for

out of round or

taper.

Any time

the crankshaft is removed from the engine it should also be checked for

runout. To perform this operation, support the crankshaft at the

front and rear main bearing journals in "V" blocks and indicate the runout of both the

rear intermediate and

front intermediate journals, using a dial indicator. The runout limit of each

of these journals is .002".

Installing Crankshaft

Blow out all cuttings from the

bearings.

Clean out

all oil passages by blowing them out with compressed air. It is good practice to

blow out each oil passage separately—this can be done by placing the fingers on the oil hole in

three of the bearings while

the nozzle of the air gun is placed in the oil inlet of the cylinder

block. After blowing out the

oil passages of all four bearings, then blow through each of the oil passages

from the main bearings to the

camshaft bearings.

Proper

cleaning of all oil passages is very important and must be done

thoroughly.

Lubricate

all four bearings and carefully place the crankshaft in the

bearings.

Check the

end-play by forcing the crankshaft to

its extreme rear position. Check at the rear side of the rear intermediate bearing with

a feeler gauge, Fig. 15. This

clearance should be from .004" to .007".

Install

the bearing caps with four .002" shims on each side and pull the bolts down

snugly. Check to see that the

crankshaft rolls freely.

Adjusting Main Bearings

Starting

with the rear bearing, remove shims evenly until there is a slight drag on the

crankshaft |

||

|

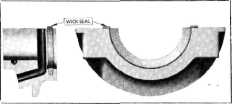

Fig. 13—Rear Main Bearing Oil Seal

into the

groove. When rolling the seal start at one end and roll it to the center

of the groove. Then starting from the

other end, again roll toward the center, as shown in Fig.

14. |

|||

|

|||

|

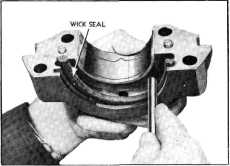

Fig. 14—Rolling Rear Bearing Cap Oil Seal into

Groove

Following

the above procedure insures that the seal is firmly pressed into the bottom of

the groove.

The small

portion of the seal which protrudes from the groove at each end after

installation should be cut

flush with the surface of the bearing cap. To prevent the possibility of pulling

the seal out of the groove it

is recommended that a round block of wood the same diameter as the

crankshaft flange be used to

hold the packing firmly in position in the groove while the ends are being

cut off.

If it

should become necessary to replace the upper half of the seal, it will be necessary

to remove the engine from

the chassis and remove the crankshaft.

The

procedure for installing the seal in the cylinder block half of the bearing is

exactly the same as for

installing it in the bearing cap.

CRANKSHAFT

One of the main reasons for the

smooth engine performance of

Chevrolet's six-cylinder engine is its rugged crankshaft. It weighs 68 pounds,

has heavy counter weights and

extra large bearing diameters. |

|||

|

|

|||