1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

|||

|

6-25 |

|||

|

|

|||

|

|||

|

|

|||

|

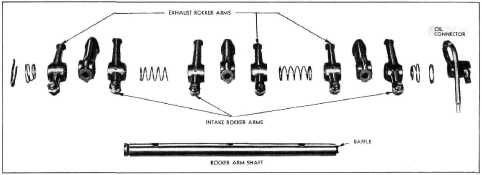

Fig. 53—Layout of Rear Rocker Arm and Shaft

Parts |

|||

|

|

|||

|

One end of

the shaft is plugged and each shaft must be installed on the cylinder head with

the open end toward the center.

A stamped steel baffle is

pressed into the open end of the rear shaft. This baffle must be installed in the vertical or

up-and-down position. The two

shafts are connected for oil feed at the center by a brass oil connector

which slips over the end of

each shaft. When removing or replacing the rocker arm and shaft

assemblies they must be handled as a complete unit.

RECONDITIONING VALVES

There is no operation, in the

maintenance of an automobile more

important than the valve reconditioning operation from the

standpoint of engine economy and

performance.

Extreme care should therefore be

used whenever valves are reconditioned

to maintain factory limits and clearances, as only by maintaining

these limits and clearances can one

expect good engine economy

and performance.

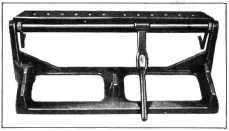

Cylinder Head Holding Fixture

The exhaust valve heads are

located in pockets |

in the cylinder head, and this

construction necessitates the use of a cylinder head holding fixture

combined with a valve spring

compressor Fig. 55, for the removal of valve springs and the

reconditioning of valves. |

||

|

|||

|

Fig. 55—Cylinder Head Holding Fixture

After the

cylinder head has been removed from the engine, and all parts disassembled from

it, all carbon should be

thoroughly cleaned from the combustion chamber, valve ports and guides,

and the head thoroughly

washed. |

|||

|

|

|||

|

|||

|

|

|||

|

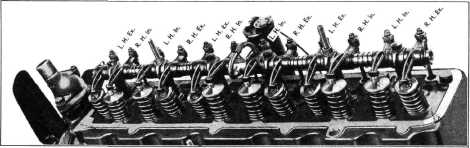

Fig. 54—Valve Rocker Arms Correctly

Assembled |

|||

|

|

|||