1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

|||

|

6-28 |

|||

|

|

|||

|

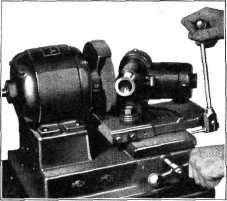

The grinding

wheel on the valve refacing machine

should be properly dressed to make sure it is true and smooth. The

valve stem is then clamped in the

chuck of the machine and the chuck set at a 30 degree angle. The beveled

face of the valve head is then

passed across the face of |

CAUTION—The cylinder head

gasket must be installed with the side marked "This side up" on top, Fig.

63, so all water passage holes and cylinder head bolt holes will line up

properly. |

||

|

|||

|

|||

|

Fig. 63-Cylinder Head Gasket

To

properly align the cylinder head to the cylinder block and keep the

cylinder head gasket in place to

prevent damage, the two cylinder head guide pins should be used.

They screw into the cylinder block at

the front and rear holes on the manifold side and guide the head into

position.

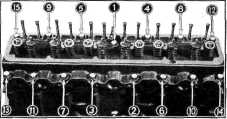

After the

head has been properly aligned, insert and tighten the cylinder head bolts with a

wrench, tightening each one

evenly a little at a time in the order shown in the cylinder head bolt

tightening diagram, Fig. 64.

The order or sequence in which |

|||

|

|

|||

|

Fig. 62—Valve Refacing Machine

the

grinding wheel until this surface is true and smooth all around the valve. Care should be

taken while grinding not to remove too much stock from the face of the valve. This is important to

prevent burning of valves in

operation.

For quiet

operation, it is important that the end of each valve stem be free from pits.

The valve should be placed in the "V" block on the refacing machine, and the end of the valve stem

ground until it is true and

smooth.

To test for

perfect valve and seat contact, mark lines with a lead pencil about 1/4" apart

on the face of the valve and

replace the valve in the head.

Give the

valve one-half turn to the right and one-half turn to the left, using a

little extra pressure on the

valve. If all pencil marks are removed, as a result of the face contacting the seat,

the grinding is perfect. If, on the other hand, one line or part of one remains untouched, this

indicates an uneven spot, and

the valve must be refaced until it seats properly.

Before replacing the valves in the

cylinder head, clean the valves and

the cylinder head. A good valve

job is frequently ruined by failure to properly clean all of

the parts,

INSTALLING CYLINDER HEAD ASSEMBLY

The best

practice is to install a new cylinder head gasket each time the cylinder

head is removed and reassembled

to the block. |

|

||

|

Fig. 64—Cylinder Head Bolt Tightening Diagram

the bolts

are tightened is important, since many water leaks between cylinders are caused by

improper tightening of cylinder head bolts.

When a tension wrench is used to

secure uniform tension on all bolts,

the recommended tension is from 75 to 80 foot pounds.

VALVE ADJUSTMENT PROCEDURE

Before

adjusting the valve-stem-to-rocker-arm clearance, it is extremely important that

the engine be thoroughly warmed up to normalize the expansion of all

parts and stabilize the oil temperature. This is very important because during the

warm-up period, the valve

clearance will change considerably. To adjust the valves during

this warm-up period will

produce clearances far from correct after the engine reaches normal

operating temperature. |

|||

|

|

|||