1942 - 1947 CHEVROLET SHOP MANUAL

Section 4 - Rear Axle, Universal Joints & Springs

|

|

|||

|

4-37 |

|||

|

|

|||

|

frame

into the body. Moreover, with this mounting, there is no metal-to-metal

contact.

Adjustment of the passenger car

rear spring seats should always be

made with the weight of the car on its wheels. The eye bolt nut should then

be loosened and the car jolted

up and down several times to

set the rubber bushings in their normal position. The eye bolt nut should then be

drawn down tight and a cotter

pin installed.

FITTING 1/2-TON TRUCK REAR SPRING SEATS

If it becomes necessary to adjust

the rear spring seats on the truck models the correct clearance

between the spring seat and the

rear axle housing may be

obtained as follows:

1. Jack up the rear end of the truck and block

it in this position by using car horses under the frame side rails.

2. Disconnect the spring shackle and drop the

rear end of the

spring.

3. Remove the spring

U-bolts.

4. Remove the two screws from the lower spring

seat cap and remove both halves of the spring seat.

5. Clamp the two halves of the spring seat in a

bench vise and file evenly

from face of each half.

Assemble the spring seat to the axle housing and check the fit of the

seat on the housing. Continue

to file evenly from both halves until such a fit is obtained that a slight drag is

felt when turning the spring

seat on the axle housing. |

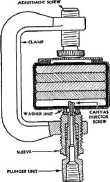

3. Set the

adjustment screw of the lubricating clamp, Fig. 70, until the width of the

clamp is a little more than

the spring thickness. |

||

|

|||

|

Fig 70—Spring Lubricating Clamp

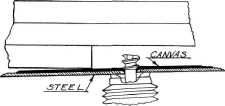

4. Push the threaded end of the plunger into

the drilled hole, forcing the

canvas against the plate.

5. Screw the plunger several times to the

right to thread the end through

the canvas, Fig. 71.

6. Screw the sleeve against the bottom of the

spring cover. Never use pliers. |

|||

|

|||

|

SPRING LUBRICATION

When

lubricating springs having metal covers, use a soft, smooth cup grease to which 8%

to 10% graphite has been

added. This compound should be

applied in such a way that it is forced between the leaves of the springs and not between

the canvas liners and the

springs covers. This can be done with the use of a spring lubricating clamp

J-595, as

follows:

1. Jack up the frame to remove the load and

allow the spring leaves to separate,

2. If the spring cover has no hole, drill a

3/16" hole in the center

of the bottom, one-third of the way from the spring

eye. |

|||

|

Fig. 71 — Position of Plunger for Lubricating

Spring

7. Attach the grease gun hose to the fitting

and apply pressure

slowly.

8. Separate the main and second spring leaves

with a screwdriver so the

lubricant can go between.

9. Remove the screwdriver and attach a "C"

clamp at the end of the spring

cover. Continuing to

apply pressure will force the lubricant

• toward the opposite

end. |

|||

|

|

|||