1942 - 1947 CHEVROLET SHOP MANUAL

Section 5 - Brakes

|

|

|||

|

5-5 |

|||

|

|

|||

|

draulic

brake fluid. This lubrication results in a better formation of the flare. Loosen

the clamping nuts on the

flaring tool and insert finished

end of the tubing in the channel of the die until it bears against the stop pin,

Fig. 9. |

flange plates have openings with

spring snap covers to simplify brake adjustment.

Toe-board clearance very seldom

needs to be adjusted. The pedal stop,

located in the brake main cylinder, is permanent. Before attempting

to adjust this stop, be certain that the pedal returns to the full

released position freely, with no binding, and that the pedal retracting

spring has not lost its tension.

TOE-BOARD CLEARANCE-PASSENGER CARS

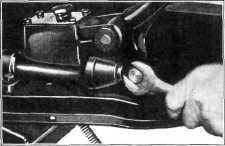

1. Loosen check nut on the eccentric

bolt.

2. Turn the eccentric bolt, Fig. 12, in the

proper direction to secure

7/16-inch toe-board clearance.

3. Tighten check

nut. |

||

|

|||

|

Fig. 9—Installing Tubing to Proper

Depth |

|||

|

Tighten

the clamping nuts by hand and place the

fixture in a bench vise. Then tighten down the clamping nuts firmly with a wrench

and remove the stop pin from

the die. The tubing is now

firmly gripped in the die and ready for the first flare forming

operation.

3. Using the flare forming tool

having the concave die, insert the

forming tool in the die and strike firm blows, using a one pound

hammer, until the shoulder of the tool contacts the top of the die. The

cross section drawing. Fig. 10, shows the first step in forming the

double-lap flare. |

|||

|

|||

|

|||

|

Fig. 12—Adjusting Pedal Toe-Board Clearance—Passenger

Cars

TOE-BOARD CLEARANCE-TRUCKS

1. Loosen the check nut on the rear of the

clevis on the main cylinder

push rod.

2. Remove clevis pin and turn the clevis

attached to the main cylinder

push rod, Fig. 13, in the proper direction to secure 1/4" toe-board

clearance—measurement being

taken between pedal arm and

underside of toe-pan.

3. Tighten the check nut against the

clevis. |

|||

|

Fig. 10—First Flaring

Operation |

|||

|

4. Next, use the flare forming

tool having the 45 degree die at its lower end. Insert the tool in the die and strike firm blows, using a one

pound hammer, until the shoulder of the tool contacts the top of

the die. The cross section drawing. Fig. 11, shows the second and final

forming operation in making a double-lap flare. |

|||

|

|

|||

|

|

||

|

Fig. 11— Finish Flaring Operation |

|||

|

HYDRAULIC BRAKE ADJUSTMENT

Chevrolet hydraulic brakes can be

adjusted without the removal of the

wheels as all brake |

|||

|

Fig. 13—Adjusting Pedal Toe-Board

Clearance—Tracks |

|||

|

|

|||