1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

|||

|

6-30 |

|||

|

|

|||

|

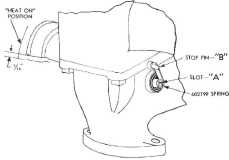

available for service under part No.

6C2799.

To install

this spring, rotate the valve weight toward engine to the "Heat Off" position,

then insert the

anti-rattle spring in slot "A," Fig. 66.

In some

cases it may be necessary to adjust this spring when installing. Hold the weight on

the manifold heat valve shaft

3/16" above the "Heat On" position and bend the spring until it

just touches the stop pin "B," Fig. 66. |

||

|

ENGINE MOUNTINGS

Cushion balanced engine mountings

are used to prevent even the smallest amount of engine vibration being transmitted to the passengers in

the car or

truck.

To adjust the engine mountings,

proceed as follows:

1. Tighten the front engine mounting bolts.

Should the mounting or

mountings be oil soaked

replacement should be made.

2. Tighten the rear engine mounting bolts at

the rear of the transmission

(passenger models only). Make

sure the mounting studs are tight in the transmission

case.

3. Check the clearance between the transmission

cross member and the "U"

section plate (passenger

models only). This clearance should he from .005" to .015", equally spaced fore and

aft. If the clearance exceeds these limits, remove the mounting and bend the "U" section plate

until the clearance is within

the above limits.

NOTE—This clearance is very

important, because it limits the fore and aft movement of the

engine.

4. (On trucks) Tighten the side engine mounting

bracket

bolts.

5. (On passenger models) Remove the bolts from

the engine side mountings and check the clearance between the mounting and its bracket

on each side, if the clearance

is more than 1/16", shim with

3/8" plain flat washer. If the clearance is less than 1/16", loosen the bracket

bolts and push the mounting

upward. (There may be sufficient clearance in the bracket bolt

holes to give the necessary

1/16" clearance). If unable to get the proper clearance in the manner

mentioned above, remove

the brackets and elongate the

holes with a round file until the 1/16" clearance between the mounting and the bracket

is obtained.

NOTE—It is important that

these mountings be set up with an equal amount of tension on each

side. |

|||

|

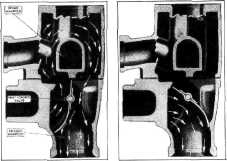

Fig. 65-Manifold Heat Riser and Heat Control

Valve

with the

result that the incoming gases will be expanded several times greater than normal

and it will be impossible to get a normal full charge into the cylinders. This, of course, reduces

power and maximum speed, makes the car lazy on acceleration, etc. Such overheating may also cause

detonation as well as

sticking valves. Therefore, it is most important that the thermostatic spring

be wound up just enough to slip

the end over the anchor pin in

the manifold and no more. This is approximately 1/2 turn of the spring

from its position when unhooked.

Whenever

the manifolds are removed from an engine, the gaskets should be examined to be

sure they are in good

condition, as leaky gaskets will cause the engine to miss. Worn gaskets

should be replaced with new.

In

assembling the manifolds to the cylinder head, the bolts should be drawn up evenly

until they are all tight. A

special wrench is necessary to properly tighten these

bolts.

Exhaust Manifold Valve Anti-Rattle Spring

An

anti-rattle spring for use on the exhaust manifold valve shaft in case a rattle

develops is |

|||

|

|||

|

Fig. 66-Manifold Heat Valve Anti-Rattle

Spring |

|||

|

|

|||