1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

|||

|

6-33 |

|||

|

|

|||

|

Coil and Condenser

The

ignition coil is of large capacity and is sealed air tight to prevent the entrance of

moisture. Transformer oil is

used for insulating material inside the coil. A large porcelain

insulator is used at the

secondary terminal of the coil, to provide effective insulation.

The condenser is also of large

capacity to operate with the large

capacity coil and distributor cam angle, and when used with these

units aids in producing high coil voltage, particularly at low engine

speeds.

NOTE—This condenser must not be

installed on models prior to 1941, as its capacity is too high for the

coil and cam angle on these models.

The

ignition coil and condenser should be checked following the instructions given by

the manufacturer of the test

equipment being used.

Fuel Pump

Remove the

pump filter bowl and screen and wash

them thoroughly in clean gasoline. When reassembling make sure the cork gasket is in

good condition and properly seated. Tighten all fuel pump

connections.

Air Cleaner

Remove the

air cleaner, wash the copper filter element in clean gasoline and allow to drain

thoroughly. Dip the element in

engine oil and allow excess

oil to drain thoroughly before reassembly.

Carburetor

Remove the carburetor from the

engine. Disassemble, inspect and

reassemble as outlined under

"Carburetor." All parts should also be checked to make sure they are correct for

the carburetor involved.

Reassemble carburetor and air

cleaner to the

engine.

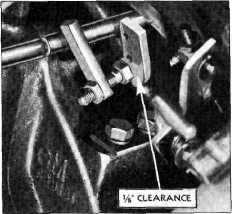

Throttle Adjustment When Starting

Provision is made on passenger

models for adjusting the amount

of throttle opening when starting the engine through a lug welded to the

starter cross shaft, and a

similar lug containing a bolt and |

check nut

for adjustment, welded to the accelerator rod, Fig 69.

To adjust

the amount of throttle opening when starting, proceed as

follows:

1. Adjust the engine idling speed at 450 to 500

R.P.M.

2. Loosen the lock nut and adjust the bolt in

the accelerator rod lug to

provide 1/8" clearance between its head and the lug on the starter

cross shaft. Fig

70. |

||

|

|||

|

Fig. 70—Adjusting Throttle Opening for Storting

This

adjustment will provide sufficient throttle opening when starting the

engine.

Manifold Heat Valve

Unhook the

thermostatic spring from its anchor pin and check the adjustment. Proper

adjustment and hook-up requires

only 1/2 turn of the spring from its unhooked position to slip it over

the anchor pin. Should this spring be distorted in any way it

should be replaced.

Valve Adjustment

Start the

engine and while it is warming up, tighten cylinder head bolts, rocker shaft

support bolts and nuts and the

manifold bolts and nuts. Where

tension wrenches are available the cylinder head bolts should be tightened to 75 to 80

foot pounds, and the rocker

shaft support bolts to 25 to 30

foot pounds.

Normalize

the engine and adjust the valves according to the procedure in this section

of the manual under "Valve

Adjustment Procedure."

Install the rocker arm cover,

using a new gasket and check for oil

leaks. |

|||

|

|||

|

Fig. 69—Passenger Car Accelerator

Rod |

|||

|

|

|||