1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

|||

|

6-35 |

|||

|

|

|||

|

the

surrounding blanket of air passing into the second venturi and this process is repeated

by the air in the main

venturi. By this means the fuel mixture is carried to the cylinders in a

more perfectly atomized

condition. This insulated atomi-zation results in increased smoothness of

operation at both low and high speeds.

The fuel

mixture quality is controlled by a metering rod operating in the metering rod

jet, and operated by the

throttle lever. There are two steps of different diameters on this

metering rod. The larger

diameter, or economy step, is tapered and controls the gasoline flow to about

seven-eighths throttle, at

which time the smaller diameter, or power step, becomes effective,

giving full power for either

high speed or hard low speed pulling. By this simple means both maximum

power and greater economy are

available without changing the

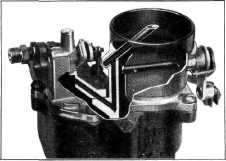

carburetor adjustment. Fig. 71 is a cross-section view of the carburetor

showing the various passages,

jets. etc.

The

carburetor used on all passenger cars and trucks (except cab-over-enginc models) is

identical and is known as the

downdraft "balanced" type. The

air pressure in the carburetor float chamber is balanced with the pressure on the inside

of the air horn by a system of

passages in the carburetor. The

air intake for the balance passage consists of a brass tube pressed into the wall of the

air horn and extending to the center of the air horn. This tube connects with a passage in the side of

the air horn as shown in Fig.

72. With this balanced pressure, the proportions of air and gasoline

in the mixture delivered to the

engine remain substantially the same at all times, even

when the air cleaner is

restricted by dirt.

The choke consists of a one-piece

choke valve, fastened by the means of

two screws to the choke shaft

which is offset to one side of the carburetor air horn. The valve is machined with an

angle on |

each end to permit solid

seating against the wall

of the air horn.

Due to the

choke valve seating against the walls of the air horn, it cannot be

damaged by backfire. The choke lever

is mounted on a boss on the air horn and is retained by a snap ring fitted

into a groove in the

boss.

The choke

lever floats on the shaft and is connected to it through a light coil spring.

This spring hooks to the choke

lever and to the choke shaft. In this way the choke valve is operated by

the choke lever through the spring.

As the

choke button on the instrument panel is pulled out, the light valve spring causes

the valve to follow the movement of the lever, closing the choke valve. As the engine starts, the rush

of incoming air through

the air horn of the carburetor overcomes the tension of this spring and

the valve automatically assumes

the correct position to provide the proper amount of air for the

mixture to enter and prevent

over-choking.

The

accelerating pump consists of a cylinder with a plunger containing an air bell and

two check valves, one on the

inlet and one on the outlet side. The accelerating pump plunger

including the shaft, guide and

leather is made as an assembly. The shaft is rectangular and bears in the

bowl cover. The inlet check valve has a bakelite disc while the outlet check valve has a brass

disc. The brass disc aids fuel economy since its weight tends to keep it on its scat and prevent lifting

from the seat due to the air

velocity in the carburetor.

The upward

movement of the pump plunger, when the

throttle is closed, draws a small metered quantity of gasoline into the bottom of the

cylinder. The slightest opening of the throttle

(downward movement of the

plunger) causes an immediate discharge through the pump jet

pointing downward into the main

venturi. This action is illustrated in Fig. 73.

Gasoline

enters the low speed jet through a 3/64" hole drilled through the jet at the recess

between the threaded

section and the base of the jet. which coincides with the low speed well in

the carburetor body, Fig. 71.

The metering hole is drilled

vertically and is .035" in diameter. This design prevents the possibility of the

engine stalling due to

gasoline surging away from this jet when the brakes are applied

suddenly.

The main

nozzle is of two-piece construction with the inner nozzle pressed into the outer

nozzle, thereby maintaining

the proper relationship between the openings in the walls of the two

nozzles. The nozzle assembly is held in place by a brass plug

having a 1/8" hole drilled through its

center. |

||

|

|||

|

Fig. 72—Carburetor Balance

Passages |

|||

|

|

|||