1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

|||

|

6-43 |

|||

|

|

|||

|

Inspection

After completing the disassembly

operations, thoroughly wash all parts

in clean gasoline or cleaning

solvent. Blow out all drilled passages in the carburetor body with compressed air in

the opposite direction to normal How of air or gasoline. Inspect and make sure the idling ports,

idle air bleed passage, and the

vacuum spark advance port are

free from carbon deposits or dirt. Check the vacuum power jet piston in its cylinder to

make sure it is free.

NOTE—Should the piston stick in

the cylinder the vacuum power jet may be in operation at all speeds. This,

of course, would result in poor gasoline economy.

Disassemble the power

jet and clean it thoroughly. Any

dirt in this jet may either stop the |

flow of gasoline at high speeds,

and result in poor performance, or the

dirt might hold the valve off its seat, and cause the power jet to be in

operation at all speeds. This, of course, would result in poor

economy.

Inspect the

accelerating pump intake and discharge check valves to make sure the ball

checks are free and seating properly. Inspect the needle valve and scat, low speed jet, main nozzle

air bleed, and main metering jet to make sure they are thoroughly

clean.

Reassembly

1. Install the main metering jet in the

carburetor body.

NOTE—There are four (4) jets

released for service for making adjustments—Part No. 603947. one-step

lean; Part No. 603948, second-step lean; Part No. 603949, third-step lean;

Part No. 603950, one-step rich.

2. Install the main nozzle idle jet and main

nozzle air bleed in the carburetor body.

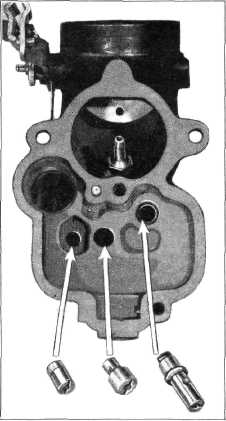

3. Install the accelerating pump intake and

discharge check valves,

vacuum power jet and tighten

them securely. Fig. 90.

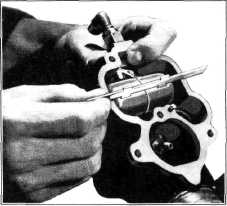

4. Install needle valve and float, assemble

float lever pin and plug

assembly. To check the float level measure from the machined surface of

the float chamber, with the gaskets removed, to the top of the float while holding the lip of

the float lever firmly against

end of the seated needle valve.

Proper float level is from 1/32 of an inch to 1/16 of an inch below top

of float chamber. Fig. 91. |

||

|

|||

|

|||

|

|

|||

|

Fig. 90—Carburetor Jet Installation |

Fig. 91-Checking Float Level |

||

|

|

|||