1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

|||

|

6-13 |

|||

|

|

|||

|

shaft by

pressure on any part of the composition.

The thrust

bearing, on the inside of the camshaft gear, when assembled to the camshaft,

determines the amount of

camshaft end play.

If there is an excessive amount of

camshaft end-play, it is necessary to remove the gear and shaft assembly and press the gear farther on the

shaft so that the thrust plate

is tight, yet free to revolve to a maximum of .003" clearance, Fig.

21.

When the

camshaft and gear are assembled to the

engine, it is important that the punch marks on both the camshaft and the crankshaft

gear be lined up, directly

opposite each other.

The

camshaft will then be in its proper position and the valves will open and close in

proper relation to the

movement of the pistons. |

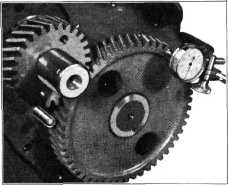

gear for

run-out with a dial indicator. This should not exceed .003". Then check the run-out of

the camshaft gear. This should

not exceed .004". The method of

checking run-out is illustrated in Fig. 22.

If timing

gear run-out is greater than specified above, remove the gear and check for burrs

on the shaft or gear that

might cause the condition. If unable to overcome the trouble in this

manner, replace the gear at fault with a new one.

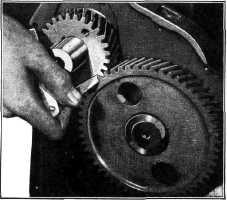

Back-lash

between the timing gear teeth should be checked with a feeler gauge as shown in

Fig. 23. The back-lash should

not be less than .002" nor more

than .005".

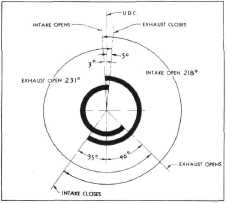

Valve Timing

Fig. 24 is the valve timing

diagram for all 1942 engines. Note

that the intake valve starts to open 3 degrees before upper dead center and

remains open for 218 degrees, closing 35 degrees past lower dead center. |

||

|

|||

|

|||

|

Fig. 22-Checking Run-Out of Timing Gears

After the

camshaft and crankshaft gears are in their proper places, check the

crankshaft timing |

|||

|

|||

|

Fig. 24—Valve Timing Diagram

The exhaust

valve starts to open 46 degrees before lower dead center and remains open for

231 degrees, closing 5 degrees

past upper dead center.

To check

the valve timing, use number 1 cylinder exhaust valve.

1. Tighten the adjusting screw to just remove

all tappet

clearance.

2. Hand crank the engine until the number 1

cylinder exhaust valve

starts to close. Continue cranking the engine until the triangular

mark on the flywheel lines up

with the pointer in the flywheel housing.

3. Mount a dial gauge on the rocker shaft

support with the spindle

of the indicator on top of |

|||

|

Fig. 23—Checklng Timing Gear

Back-Lash |

|||

|

|

|||