1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

|||

|

6-15 |

|||

|

|

|||

|

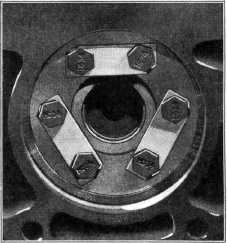

HARMONIC BALANCER

The harmonic balancer consists of

a small flyweight attached to

and driven by the crankshaft through two rubber annular rings mounted

over six studs riveted to the hub.

When the

engine is running, any change in the speed of the crankshaft, which would cause

vibration, will be

resisted by the action of the balancer. This resistance is produced by a floating

action between the rubber annular rings and the six driving

studs. The flyweight moves back and forth on the rubber mounted studs in

the opposite direction to that of the

crankshaft, and thereby dampens out or absorbs crankshaft

vibrations.

Due to the

construction of the balancer the parts are not serviced separately. The

1942 harmonic balancer is

interchangeable with 1941 models but not with previous models, due to a

difference in length.

The

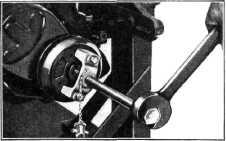

harmonic balancer puller, Fig. 28, is made in three parts, a drop forged puller body, a

puller screw and a driver head. The driver head is made of tool steel with a drill rod pin which is

replaceable. |

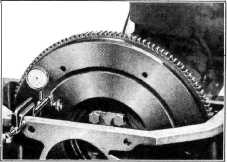

FLYWHEEL

Chevrolet flywheels are made from

the very best grade of cast iron, and

have a steel ring gear shrunk on the outer diameter, with which the

starter drive pinion meshes when starting the engine.

The

flywheel is accurately balanced to assure smooth engine operation at all speeds, and

is properly located on the

crankshaft flange by three dowels. Attachment to the crankshaft is by

six special large head cap

screws locked by lock plates.

Fig. 29. |

||

|

|||

|

|||

|

Fig. 29-Method of Locking Flywheel Bolts

After the flywheel has been

assembled to the crankshaft, it is

necessary that the face and the rim of the flywheel be checked for

run-out. |

|||

|

Fig. 28—Harmonic Balancer Puller and Driver

In

operation the puller body is attached to the balancer by means of the two cap screws in

the puller, which screw into the tapped holes in the balancer. This

insures the puller body being held firmly against the balancer and helps to

hold the balancer together while it is being removed. Next turn the puller screw into the body until

the balancer is removed. This puller provides a steady

pull on the balancer allowing

its removal without damage.

When installing the balancer the

puller body is removed, the driver

placed in the starting crank jaws and the puller body reassembled to the

balancer. Next line up

the key in the crankshaft with the keyway in the balancer and drive the

balancer in position using the

puller screw as a driver. If the puller is assembled in any other

than this way serious damage will be

done to the balancer. |

|||

|

|||

|

Fig. 30-Checklng Flywheel Run-

Out |

|||

|

|

|||