1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

|||

|

6-27 |

|||

|

|

|||

|

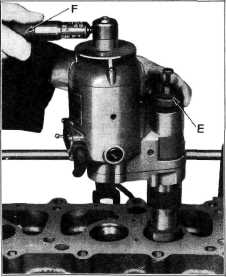

Place the grinder over the

expanding pilot, then loosen the Allen

set screw "B," Fig. 58, and push down the adjusting rod "C" against the

top of the pilot. Then lock the

set screw "B" tightly. |

into the

valve seat by turning the feed screw "E" to the left one notch at a time until the

wheel is grinding all around the face of the valve seat.

Before shutting off the

grinder, stop feeding the wheel into the valve seat and give it time to

grind itself free. Turn off the switch and allow the grinder to

stop before lifting it from the

pilot.

Mount the

valve seat dial indicator on the pilot, set at zero and turn the sleeve of

the indicator with thumb

and finger. When the seat is properly ground, the indicator reading will

be within .001", Fig.

60.

The valve

seats should now be narrowed down to

the proper width which is 3/64" to 1/16" for the intake valve seats and 1/16" to 3/32"

for exhaust valve seats.

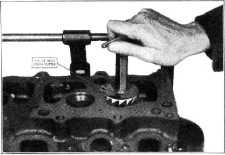

This operation is done by machining both the port and the top of the valve

seat. A 70-degree grinding

wheel should be used in the intake and exhaust ports, and a 20-degree grinding

wheel to thin down the exhaust

seats from the top. A form cutter, KMO-105-7, must be used to thin

down the intake valve scats

from the top, Fig. 61. This tool, at the same time, machines the

edge of |

||

|

|||

|

|||

|

Fig. 59—Grinding Intake Valve Seat in Head

Turn the

feed screw "E," Fig. 59, to the right until the grinding wheel just clears the

seat. Balance the grinder

with the compensating handle "F." Start the motor and feed the grinding

wheel |

|||

|

|||

|

Fig. 41—Using Cutter to Narrow Intake Valve Seat

the valve

recess in the head, thereby smoothing this passage for the free flow of the

incoming gases.

Good judgment must be used when

narrowing a valve seat to make sure

the seat contacts the center of the valve face. This is very

important because the life of a valve reconditioning job

depends to a great extent upon the

width of the valve seat and

point of seat contact with the valve face.

If the

valve seat in the head is too narrow, heat will not be dissipated from the valve head

fast enough. If too wide,

carbon particles can be readily caught between the valve face and seat,

causing the valve to hold open

and blowby, which will soon

burn both the valve and the seat in the head.

Refacing Valves

Valves

that are pitted can be refaced to the proper angle, insuring correct relation

between the head and stem, on

a valve refacing machine illustrated in Fig. 62. |

|||

|

Fig. 60—Checking Valve Seat with

Indicator |

|||

|

|

|||