1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

|||

|

6-32 |

|||

|

|

|||

|

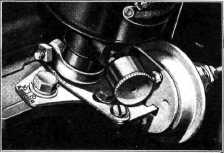

Ignition Distributor

The

ignition distributor is designed to operate with a polarity reversing switch which

reverses the polarity or

direction of current flow, through the distributor points thereby greatly lengthening

their life. The breaker plate

is completely insulated from the distributor body by a strip of

insulating material extending

from one distributor cap clamp location to the other. The screws attaching these

clamps to the distributor body

are screwed into nuts made of insulation material located inside the

breaker plate lugs. One

primary terminal is located in the distributor body and insulated the same as on

former models; the other

primary terminal is insulated from the distributor body and screwed into a

lug on the breaker plate. The

breaker cams have a steep

angle, insuring that the breaker points remain closed for the greatest number of degrees

of cam rotation, thereby

permitting current to flow through the primary winding of the coil a greater

length of time. This results

in greater magnetic saturation of the coil which in turn increases the

coil output of secondary

current. Fig. 67 shows the ignition distributor. |

the trouble corrected. See

instructions for this operation in

Section 12 of this Manual.

Examine

the distributor points. Dirty points should be cleaned, and pitted or worn points

should be replaced. Check the

points for alignment, and

align them if necessary.

Hand-crank

the engine until the distributor point

cam follower rests on the peak of the cam. Adjust the point gap to .018", using a

feeler gauge. This operation

must be performed very accurately because it affects the point dwell or

length of time the points

remain closed in operation and, in turn, ignition coil

performance.

Hand-crank the engine until the

cam follower is located between the cams. Hook the end of a distributor point scale over the movable point

and pull steadily on the spring

scale until the points just start to open. At this point the

reading on the scale should be

between 17 and 21 ounces.

Check to

see that the vacuum spark control operates freely by turning the distributor

body counterclockwise and see

that the spring returns it to

the retarded position. Any stiffness in the operation of the vacuum spark control will

affect the ignition timing.

Ignition Timing

Set the

octane selector at "O" on the scale, Fig. 68, and attach a Neon Timing Light to No. 1

spark plug. Start the engine

and run it at idling speed. Loosen distributor clamp and rotate the

distributor body clockwise and

counterclockwise until the steel ball in the flywheel lines up with

the pointer on the flywheel housing. Tighten the distributor clamp screw. |

||

|

|||

|

|||

|

Fig. 67—Ignition Distributor

Remove the

spark plug wires from the distributor cap and examine the terminals for

corrosion. The wires should be

checked for damaged insulation and oil soaked

condition.

Remove

the distributor cap. Check the cap and distributor rotor for cracks or burned

contacts.

Check the

distributor automatic advance mechanism by turning the distributor cam in a

clockwise direction as

far as possible, then release the cam and see if the springs return it to its

retarded position. If the cam

does not return readily, the distributor must be disassembled and the

cause of |

|||

|

Fig. 68—Octane Selector

Reassemble

the distributor cap and spark plug wires. Make sure that all terminals of the

primary wire at the ignition

coil, reversing switch and distributor are clean and

tight. |

|||

|

|

|||