|

1949 Delco Brakes Service Manual (Courtesy of Pat Gizz) |

|||

|

DELCO BRAKE SERVICE MANUAL |

|||

|

|

|||

|

CAUTION: When using the filler

jar method operate the brake pedal slowly, otherwise air may be drawn

into the system. It will be found necessary to depress the brake

pedal approximately 10 times to bleed each wheel

cylinder. |

bled; tighten bleeder valve;

remove bleeder hose;

always replace bleeder

screw.

CAUTION: In some cases, when

using a pressure

tank, air bubbles form in the

tank. This difficulty can be avoided if the following suggestions are

carried out: (1) Do not shake or agitate the pressure tank after air

pressure has been added or is being added. (2) Allow pressure tank to

stand in one position as much as possible, and bring air hose over to tank

when adding head of air. (3) Make certain the valves on the pressure tank

lines are not defective

allowing air to be sucked in when fluid passes through the lines.

(4) Pressure tank should be kept at least 1/3 full of fluid to

avoid air bubbles forming. (5) If pressure tank is full of air bubbles,

release air pressure and these bubbles will increase in size and be forced

to top of fluid, and escape.

Fluid drawn out in the

bleeding operation should not

be used again.

INSTRUCTIONS FOR FLUSHING

Safe, efficient, dependable

operation of hydraulic brake controls depends greatly upon the system

being kept clean and free from foreign

matters, gum, etc., and upon the fluids having and retaining the

proper characteristics. Past experiences with hydraulic brakes have shown

definitely that dirt does get into the system, causing leaks and,

eventually, brake failure. Many brake fluids become thick, resulting

in inefficient brake operation; other fluids will break down under hard

usage, causing eventual loss of braking action.

So that the hydraulic brake

system will operate at its best at all times, the brake system should be

cleaned, flushed, and refilled every 10,000 miles. This will remove all

dirt accumulation in the System and insure proper level of brake

fluid. Declene, a specially compounded fluid, is recommended for flushing

the brake system. Declene is available in quart cans—enough to service one

car. (See Figure 12.) It is red in color to help distinguish it from brake

fluid and as a means of indicating when it is coming through the line

clean.

Two methods of flushing are

commonly used, namely—washing the master cylinder with Declene fed from a

gravity filler jar and pumped through the system by working the brake

pedal slowly, or forcing the Declene into the master cylinder

reser- |

||

|

|||

|

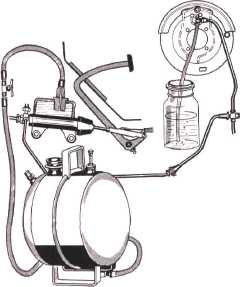

Fig. 11B—Bleeding Delco Hydraulic Brake

System

When using filler jar, the master

cylinder should always be re-filled after bleeding each wheel

cylinder so that no air gets into the system. When bleeding operation is completed, be certain that

the master cylinder reservoir

is filled to the proper level.

(B) If the pressure tank method

is used, remove filler cap assembly on master cylinder and make sure that

the master cylinder reservoir is filled with fluid; make certain pressure

tank hose is filled with fluid, then

attach to master cylinder. Prepare wheel cylinder for bleeding as

outlined under filler jar method; apply pressure to hydraulic brake

system not to exceed 35 pounds. Too much pressure may blow out the

expansion plug in the master cylinder fluid reservoir. When using the

pressure tank, it is not necessary to pump the brake pedal to bleed the

system. When bubbles of air stop coming from bleeder hose, that particular cylinder and

line are |

|||

|

|

|||

|

9 |

|||

|

|

|||