|

1949 Delco Brakes Service Manual (Courtesy of Pat Gizz) |

|||

|

DELCO BRAKE SERVICE MANUAL |

|||

|

|

|||

|

commonly known as a

self-energizing type which means that the secondary shoe pressure exerted

against the drum, due to the action

of the wheel

cylinder, is increased

substantially as the result of wrapping action of the primary shoe during

forward movement of the car. The effect is that lighter brake pedal pressures are required on the

part of the operator.

Hydraulic pressure, developed in

the master cylinder as the result of brake pedal movement, is in turn

distributed to the four brake assemblies by means of pipe lines. This

pressure is then converted into mechanical movement by the wheel cylinders

which expand the brake shoes and linings and bring them in contact with the drums. The amount

of force exerted by the wheel

cylinder is dependent on (1) the pressure exerted in the master

cylinder, and (2) the wheel cylinder piston size—the larger the piston the

greater the mechanical force. The initial brake pedal movement stops when

shoe clearances ore taken up,

and further pressure on the brake pedal produces correspondingly

higher pressures within the hydraulic system causing greater force to

be exerted by the brake shoes and linings against the drums. The driver's

effort is multiplied on the master

cylinder piston by the leverage of the brake pedal. The mechanical

advantage at the beginning of the pedal stroke is approximately

7-1/2 to 1; near the floor mat, it is approximately 6 to

1. This is a good reason for keeping brakes properly

adjusted.

As the brake pedal is allowed to

return to the released position, the hydraulic pressure is relieved and brake shoe retracting springs draw the

shoes together, pressing the wheel cylinder pistons

and |

cups back toward each other

inside the wheel cylinder, thus causing the brake fluid to flow back

through the pipe lines into the master

cylinder.

SERVICE

INSTRUCTIONS

The mechanic should, first of

all, carefully determine from the car owner all of the peculiar

characteristics of the brakes on his car. By so doing and by using

the Trouble Diagnosis Chart near the end of this manual, it is possible to

correct existing but perhaps not apparent troubles, such as a broken or

weak return spring, improper fluid, air in hydraulic brake system, etc.

Prior to making minor or major brake adjustments, always remove the right

front wheel so that the customer can see the condition of his brakes and

lining. At the same time, point out to the customer any signs of wear on king bolt,

shackles, and steering mechanisms; loose backing plates; unequal tire pressure or other

conditions that might affect

brake operation. |

||

|

|||

|

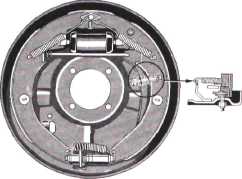

Fig. 15—Delco Hydraulic Brake Assembly

(Typical) |

|||

|

|

|||

|

MINOR BRAKE

ADJUSTMENT |

|||

|

|

|||

|

(Covers adjustment for lining

wear when readjustment of anchor pin is not necessary.) Note:

General condition of linings on all four wheels can usually be determined by removing right

front wheel and inspecting linings.

To

determine whether anchor pin is in correct position, proceed as

follows: |

Insert a feeler gauge through the

inspection hole in the drum between the secondary lining and the drum

about 1-1/2" from the anchor pin end of the lining. (See Special

Instructions for Buick under "Major Brake Adjustment.") Should the

clearance be greater than .012" or less than .005", the anchor pin must be

readjusted. (See "Major Brake Adjustment" for

procedure.) |

||

|

|

|||

|

12 |

|||

|

|

|||