|

ROCHESTER CARBURETORS Bulletin 9D-95 February 1953 |

|||||

|

FLOAT LEVEL ADJUSTMENT |

|||||

|

|

|||||

|

With the

air horn gasket in position and the air horn inverted on a flat

surface:

a. Carefully bend float arms vertically until

floats appear level in

relation to each other.

b. Place float gauge BT-87 in position

so that the gauge is located

against the curvature in the bore of the carburetor air horn, and is

centered above each

float.

c. Adjust both floats together by bending

the |

arm at the rear of the float

assembly. Bend the arm until each float just

touches the top portion of the gauge between the gauge legs. (The scale

dimension from the gasket to the

bottom of each float is 1 9/16".)

d. Then

bend arms horizontally until each float is centered between the gauge legs. Tilt the

air horn assembly 90" each way

and check that floats do not

touch gauge legs. This insures that floats will not rub sides of float

bowl. |

||||

|

|

|||||

|

FLOAT DROP ADJUSTMENT |

|||||

|

|

|||||

|

Bend the float tang at the rear of

the float assembly, against the needle seat to lessen the drop and

away from the needle seat to increase the drop. The tension is correct

when the scale dimension |

from the bottom of the air horn

gasket to the bottom of the floats, with the air horn held in an upright

position, is 2-1/2". |

||||

|

|

|||||

|

4. The

Accelerator Pump System of the 1953 Model 4GC Carburetors is basically the same

in theory of operation as the

1952 models. However, a few

changes in design and calibration have been made for ease of service and improved

performance. |

CHECK VALVE SPRING SPRING

GUIDE |

||||

|

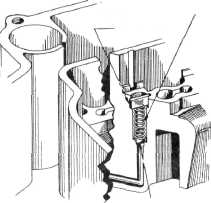

Refer to figure 2

The brass pump discharge needle

used on 1952 models has been replaced by a ball check valve spring and retainer. This type of outlet

check serves to hold the ball check on its seat regardless of road

conditions or severe brake applications. |

|||||

|

Refer to figure 3

The brass

pump discharge jets used on 1952 models

have been replaced by two drilled and calibrated discharge holes. As shown, two "U"

shaped cups have been added to the venturi cluster adjacent to these

discharge holes. As the air passing through the carburetor under high velocity strikes

these cups the air pressure at

the pump discharge holes is in a state of balance, thus eliminating the

possibility of pump pull-over.

With this improved design, the use of a pump discharge vent valve is no longer

required.

NOTE: From the above discussion,

it can readily be seen that many parts for the 1953 model 4GC carburetors

have been redesigned and recalibrated and are, therefore, not

interchangeable with those used on 1952 models. Always consult the

application index and parts lists for correct service parts and

adjustment information. |

|||||

|

BALL CHECK VALVE |

|||||

|

Figure 2 |

|||||

V SHAPED

CUPS |

PUMP DISCHARGE HOLES |

||||

|

|

|||||

|

RP Form 1105 |

Printed in

U.S.A. |

Figure 3 |

|||

|

|

|||||