|

ROCHESTER CARBURETORS Bulletin 9D-9 January 1952 |

|||

|

Page 5

ROCHESTER PRODUCTS, DIVISION OF GENERAL MOTORS,

ROCHESTER, NEW YORK |

|||

|

|

|||

|

OPERATING SYSTEMS |

|||

|

|

|||

|

IDLE SYSTEM

|

|||

|

|

|||

|

|

|||

|

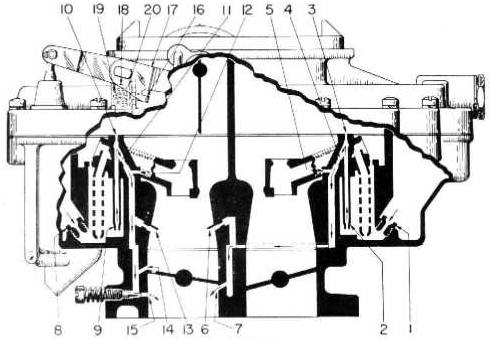

Figure

7-1 |

|||

|

|

|||

|

At small throttle openings, the

vacuum created at the main discharge nozzles is not great enough to cause

fuel to flow from the nozzles. Therefore, additional systems have

been introduced to provide the proper mix-lure ratios required throughout

the low speed range.

A fixed idle system is provided on

the secondary or fuel inlet side of the carburetor. '1 his system provides

about half the required fuel for normal curb idle mixtures. As shown

in figure 7-1. the secondary idle fuel is drawn from the float bowl

through the main metering jets (1). into the fuel well in the bottom

of the float bowl. It then passes through the calibrated restrictions in

the ends of each idle tube (2). The fuel is then drawn up through the idle

tube, is bled at the idle bleeds (3),

passes through calibrated restrictions (4) and is again bled by the

calibrated bleeds shown at (5). The mixture is then drawn through the

channel in the float bowl around the secondary throttle body bores, is

further bled by the lower idle air bleeds (6) and is discharged from the

throttle body idle orifice (7). As the throttle is opened, the

vacuum or suction on the idle discharge holes (7) decreases very rapidly.

These discharge holes, therefore, stop feeding fuel in the off idle

range.

In addition, an adjustable idle

system is provided on the primary or pump side of the carburetor. This

system provides the balance of fuel required for normal curb idle as

well as that required for operation in the off idle, low speed range.

Refer again to figure 7-1. The primary idle fuel is drawn from the float

bowl through |

the main metering jets (8) into

the fuel well in the bottom of the float bowl. It then passes through

the calibrated idle tube restrictions (9), and idle tubes. Air

joins this fuel at the calibrated bleeds (10). This mixture then

passes through the calibrated restrictions (11) and is bled further at the

secondary idle bleeds shown at (12). The mixture then passes through the

float bowl idle channel, is further bled at the lower idle air bleeds

(13) and secondary idle holes

(14), and is discharged from the throttle body idle needle holes (15). As

the throttle valves are opened, the bleed effect of the secondary

idle holes gradually diminishes. When these holes become exposed to

manifold vacuum they then become fuel discharge holes to meet the

increased demand of the engine.

To minimize difficult hot weather

starting or rough idling due to fuel vapor formation the Model 4GC

Carburetor incorporates an external vent when the throttle valves are in

the closed position. This external idle vent consists of an actuating

lever (16) attached to the pump shaft and lever assembly (17), idle vent

valve guide (18), idle vent

valve spring (19), and idle vent valve (20). When the throttle valves are

closed, the actuating lever contacts the spring loaded vent valve and

holds it open, permitting vapors from the float bow] to vent themselves to

the atmosphere. As the throttle valves are opened, the idle vent spring

closes the vent valve thus eliminating the atmospheric vent and

returning the carburetor to an internal

balance. |

||

|

|

|||