|

ROCHESTER CARBURETORS Bulletin 9D-9 January 1952 |

|||

|

Page 9 |

|||

|

|

|||

|

ROCHESTER PRODUCTS, DIVISION

OF GENERAL MOTORS, ROCHESTER, NEW YORK |

|||

|

|

|||

|

FLOAT SYSTEM

|

|||

|

|

|||

|

|

|||

|

|

|||

|

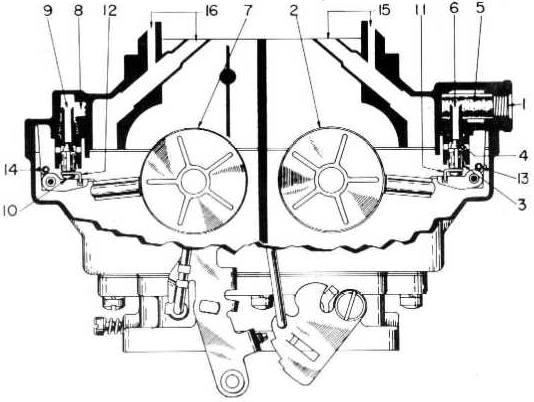

Figure 7-5 |

|||

|

|

|||

|

To aid in maintaining the correct

fuel level under all conditions of operation, the Model 4GC Carburetor

employs the use of two sets of twin floats.

Use Figure 7-5 as a

reference.

Both sides of the carburetor

incorporate individual float systems for maintaining the proper fuel level

in each float bowl. All fuel enters the carburetor on the secondary or

fuel inlet (1) side.

As the fuel level on the secondary

side drops, the twin floats (2) also drop, thus moving the inlet needle

(3) off its seat (4). Then pressure, from the fuel pump, forces fuel

through the filter screen (5). into the inlet passage (6), and the float bowl. As the fuel

level rises, the floats rise and once again close off the inlet

needle.

As fuel is drawn from the float

bowl on the primary or pump side of the carburetor, the float action is

identical with that on the secondary side. As the twin floats drop

(7). pressure from the fuel pump forces fuel through the fuel inlet (1)

and filter screen (5). This fuel then passes through a channel cored in

the air horn and enters the inlet passage on the primary side at (8). It

then passes through the needle seat channel (9), past the now open inlet

needle (10), and into the float bowl. As on the secondary side, when the

fuel level rises, the floats rise and once again close off the inlet

needle. |

Both float systems are provided

with float needle pull clips (11 & 12) (on some model 4GC Carburetors

only) and float balance springs (13 & 14). The float needle pull

clips link together the twin floats and the inlet needles, thus causing

the inlet needles to retract from their seats upon a drop in fuel level in

the float bowls. This is to prevent the possibility of gum deposits

causing a sticking condition. The balance springs act as vibration

dampeners and enable the carburetor to maintain a more constant and

accurate fuel level.

Both sides of the carburetor are

individually and internally vented by the channels shown in 15 and

16. These vents transmit the pressure from beneath the air cleaner to the

fuel in the float bowl. The amount of fuel metered by the carburetor is

dependent upon the pressure in the float bowl causing fuel to flow. By

locating the vents below the air cleaner, or internally, the

carburetor automatically compensates for air cleaner restriction, since

the same pressure causing air to flow will also be causing fuel to

flow.

A cored passage in the float bowl,

slightly above the normal fuel level, links the primary and secondary

float bowls together. In this way any abnormal rise in level on one side

will be absorbed by the other and should not seriously disrupt the

operation of the engine. |

||

|

|

|||