|

ROCHESTER CARBURETORS Bulletin 9D-9 January 1952 |

|||

|

Page 8

ROCHESTER PRODUCTS, DIVISION OF GENERAL MOTORS,

ROCHESTER, NEW YORK |

|||

|

|

|||

|

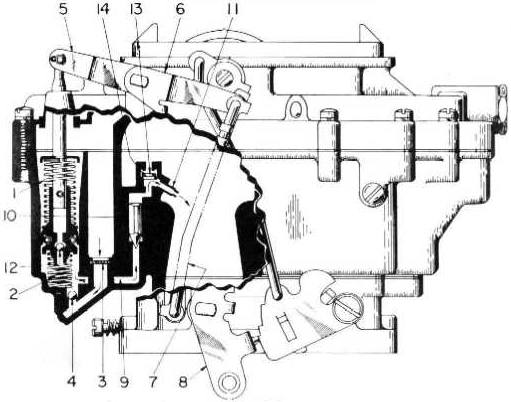

ACCELERATING PUMP SYSTEM |

|||

|

|

|||

|

|

|||

|

|

|||

|

Figure 7-4 |

|||

|

|

|||

|

When the throttle is opened

rapidly the air flow and

manifold vacuum change almost instantaneously while the heavier fuel tends

to lag behind causing a momen-tary leanness. The accelerator pump provides

the fuel necessary for smooth

operation on rapid acceleration.

Use Figure

7-4 as a reference.

Since the throttle valves on the

secondary or fuel in-let side of the carburetor remain fully closed

throughout part throttle operation, it is only necessary to have

one accelerator pump, that being

located on the primary or

pump side of the carburetor.

A double spring pump plunger is

used on the Model 4GC Carburetor. The

rates of compression of the top spring (1) versus the bottom spring (2) are carefully calibrated to

insure a smooth, sustained charge of fuel for acceleration.

On the pump intake or up stroke

fuel from the float bowl passes through the pump filter screen (3), unseats the aluminum inlet ball

(4) and fills the pump well.

The accelerator pump, being

connected, through the inside pump lever (5). pump shaft, and lever

assembly (6) and pump rod (7). to the throttle lever (8) moves at the slightest change in

throttle opening. Upon acceleration or down stroke of the pump

plunger, the force of fuel in the pump well seals the inlet ball (4). The

fuel is then forced through the discharge channel (9) unseals the pump outlet needle (KM. and

discharges through the pump jets (11) into the main air stream. No targeting of these

pump jets is required. |

The Model

4GC Carburetor accelerator pump system is vented twice for peak operating

efficiency.

The pump plunger head has been

vented to minimize the effect of fuel percolation in the float bowl pump

well. This has been accomplished by

the design of a ball check and seat in the plunger head (12). In this manner any build up of fuel vapors in the pump

cylinder will rise and by-pass the ball, thus venting themselves

into the float bowl. There is,

therefore, always a charge of solid fuel beneath the plunger head for

rapid acceleration. Without this feature, any vapor pressure build up

would evacuate the charge of fuel in the pump system, thus causing poor initial

acceleration as well as difficult hot weather

starting,

The atmospheric vent valve is

located in the primary Venturi cluster (13) in the channel above the pump

discharge jets. Upon sudden

acceleration, the force of fuel past the outlet needle seats the

valve in its "up" position, thus

preventing a discharge of fuel through the vent passage. Under constant

throttle conditions, the weight of the valve causes it to rest

against its spring retainer

(14), thus permitting air to flow from the inside bore of

the air horn, through the vent

and into the chamber above the pump outlet needle. This vent valve

utilizes the suction at the pump jets by progressively increasing the

force tending to scat the outlet needle, with each increase in throttle

opening. This prevents a condition

known as pump pullover, or a discharge of fuel from the pump jets during high speed

operation. |

||

|

|

|||