1942 - 1947 CHEVROLET SHOP MANUAL

Section 12 - Electrical System

|

|

|||

|

12-13

|

|||

|

|

|||

|

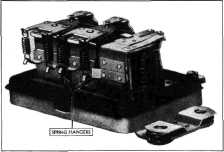

Current setting of the

regulator is adjusted by bending the spiral spring hanger down to

increase the current setting, or bending up on the spring hanger to

decrease spring tension and lower current setting, Fig. 25. Normally,

all adjustments should be made on one spring and the other spring

should not be touched.

|

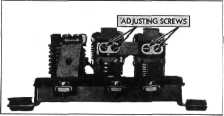

Adjustment of this air

gap may be made by loosening the screws which mount the upper contact

support, two left screws in Fig. 26. The support may then be moved up

or down as required to provide an air gap of .075" to .085".

NOTE -Be sure

points are lined up and tighten screws down well after adjustment.

VOLTAGE REGULATOR

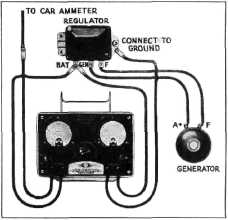

When checking the

voltage regulator, connect the volt ammeter tester to the regulator as

follows:

Remove the battery

wire from the battery terminal of the regulator and connect the

positive lead of the ammeter to the battery terminal and the negative

lead to the battery wire.

Then connect the

positive lead of the voltmeter to the battery terminal of the

regulator and the negative lead to a good ground, Fig. 27. Start the

engine and run it at a speed equivalent to approximately 30 M.P.H.

|

||

|

|||

|

|

|||

|

Fig. 25-Current Regulator Lower Spring Hangers

If the unit is badly

out of adjustment, it may be necessary to remove one tension spring

and adjust by means of the other tension spring only for its proper

setting. With the generator operating at medium speed, adjust the

tension of the one spring by bending its hanger up or down until the

current regulator unit operates at approximately 17 amperes. Next

install the second spring and complete adjustments entirely on this

spring to 34 to 36 amperes as previously explained without again

touching the first spring. The final adjustment must be made lightly

on the second spring.

In some cases it may

be necessary to readjust the air gap between the armature and core. To

check this adjustment push the armature down all the way by hand, then

allow it to come back up until points are just touching. Then measure

the air gap, which should be from .075" to .085".

|

|

||

|

Fig. 27-Volt Ammeter Connections for Checking

Voltage Regulator

If the output is less

than 8 amperes, turn on lights to permit increased generator output,

then cut in the resistance on the volt amperage tester by turning the

resistance knob to the right until the output is reduced to 8 to 10

amperes. Operate the generator at this speed for at least 10 minutes

to bring the regulator up to operating temperature. Retard the

generator speed until the circuit breaker points open, then bring

generator back to speed and note voltage setting, which should be from

7.2 to 7.4 volts.

NOTE -When checking

voltage regulator setting the regulator cover must be in place.

|

|||

|

|||

|

Fig. 26-Air Gap Adjusting Scrawl

|

|||

|

|

|||