1942 - 1947 CHEVROLET SHOP MANUAL

Section 12 - Electrical System

|

|

|||

|

12-14

|

|||

|

|

|||

|

VOLTAGE SETTING

Stop the engine and remove the regulator cover. The voltage setting of

the regulator is adjusted

|

In case the voltage

does not respond to a slight movement of the spring hanger, the

following adjustments are

necessary:

1. Clean

the regulator points according to instructions given in the repair

section.

2. Adjustment

of the air gap-Push the armature

down all the way by hand. Allow

it to come back up until

points are just closing; then

measure the air gap with a feeler

gauge. The distance

between the armature and the core

should be .075" to .085". The air

gap may be adjusted by

loosening the two upper contact

mounting screws and moving the

upper contact support up or

down as required to secure the

proper air gap, two rights screws

in Fig. 26. Be sure that points are lined up and tighten screws

down well after adjustment.

CLEANING CONTACT POINTS

Cleaning the contact points of the current and

voltage regulator properly is one

of the most important

operations the service man will be called

on to perform. Dirty or oxidized

contact points arc and burn, cause reduced generator output,

and run down batteries. If the

points are properly cleaned

the regulator will be restored to normal

operation. If improperly cleaned,

improvement in performance

will be small and only temporary.

Remove the upper contact support, so that each point may be properly

and separately cleaned. Use a

thin, fine-cut ignition point file and file each point

separately. Do not use the file

excessively on the rounded

(smaller) point. If a cavity is found in

the flat point, clean it out with

a spoon or riffler file,

Fig. 29. Make sure the cavity is actually

cleaned out, so good, clean

contact is made between the

points. Reassemble contact supports, paying

particular attention to the

position of the insulators, and adjust the air gap.

|

||

|

|||

|

Fig. 28-Voltage Regulator Lower Spring Hangars

by bending the spiral spring hanger down to increase

the spring tension and increase the voltage setting, or by bending the

spring hanger up to decrease

the spring tension and lower the voltage.

Fig. 28. Normally, all adjustments

should be made on one spring and the other spring should not be

touched.

On voltage regulators that are badly out of adjustment

after the points have been cleaned and

the air gap set. it may be

necessary to check the

adjustment of the second spring. To do this, remove

one spring from the regulator; connect the positive lead of the

voltmeter to the generator terminal

of the regulator and the negative lead to a good ground.

Depress the voltage regulator armature

by hand to open the points. Slowly increase the generator speed

until the voltmeter reads approximately

3 volts. Release the armature and

adjust the spring hanger up or

down to secure a voltage

reading of 4.5 to 5 volts. Install the other

spring and complete the adjustment

to 7.2 to 7.4 volts

entirely on this spring, as previously explained,

without again touching the other spring.

NOTE -When the

above adjustments are being made, the unit must be at operating

temperature and the cover must be in place when voltage readings are

taken.

After any adjustments, replace the cover, start

the engine, and set it to run at

a speed equivalent to 30 to

35 miles per hour. Readjust the variable

resistance in the volt ammeter to

obtain a generator output of 8 to 10 amperes. Now check the

regulator voltage, which

should be within the limits given above.

NOTE -Only a slight

bend of the lower spring hanger is necessary to change the voltage

setting.

|

|||

|

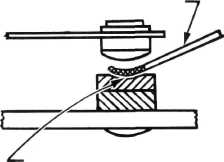

RIFFLER FILE

|

|||

|

|||

|

OXIDIZED CAVITY

EXAGGERATED VIEW

Fig. 29-Cleaning Flat Regulator Point

|

|||

|

|

|||