1942 - 1947 CHEVROLET SHOP MANUAL

Section 12 - Electrical System

|

|

|||

|

12-19

|

|||

|

|

|||

|

ground. This will

operate the generator as a motor.

The ammeter reading, with the generator running, should be from

4 to 6 amperes.

When motoring voltage regulated generators,

make sure to connect the positive

of the battery to the

positive terminal of the generator, otherwise

the residual magnetism of the

generator will be reversed,

thereby reversing the polarity of the

generator.

After overhauling a

voltage regulated generator, the

voltage setting and the generator output (amperage) should be

checked on the car or truck as described earlier in this section.

NOTE—It is good

practice, after reassembling a generator on the car or truck, to use a

juniper lead to momentarily connect the battery terminal of the

regulator with the generator terminal. This sends a current through

the generator windings, assuring that if will build up in the proper

polarity.

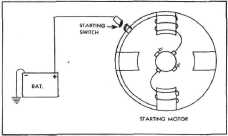

THE STARTING SYSTEM

The starting system has only one function to

perform—to crank the engine. In

the starting system, there are three units: the battery, the starting

switch and the starting motor, Fig. 41.

|

THE STARTING MOTOR

The starting motor is similar in construction and appearance to the

generator, but the design of the

parts is different. Both motor and generator require

frame, field coils, armature, brushes, etc. The

operation of the starting motor is

the reverse of the

generator. In the case of the generator, a loop of

wire is revolved in the magnetic

field and generates current. In the case of a starting motor,

current is supplied to the loop

which lies in a magnetic field. As the loop rotates, mechanical energy

is produced.

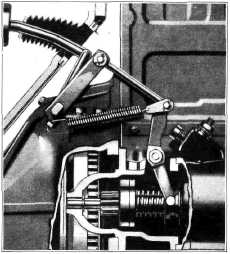

The starting motor is designed to incorporate a

manual shift drive mechanism

which assures positive

engagement of the starting motor pinion with

the flywheel until the engine is

started, Fig. 42. This is of particular benefit when starting a

cold engine, as the starting

motor will continue to crank

the engine as long the the driver

depresses the starter

pedal.

In this design, the starter pinion in conjunction

with an over-running clutch (or

roller clutch), a

compression spring and pulley-like sheave are

mounted as an assembly on the

splined part of the armature shaft. The sheave and spring are mounted

to rotate freely on the outer diameter of the tube portion of the

assembly. Fig. 42.

|

||

|

|||

|

|||

|

Fig. 41-Starting

Motor Circuit

The battery supplies the energy, the switch completes

the circuit, allowing this energy to flow to the starting

motor. The motor then delivers mechanical

energy and does the actual work of cranking the engine. The starting

equipment is used for a

short time only and then remains idle until it is

again needed to start the engine.

The battery, however,

performs other functions.

It should be noted that the starting motor draws

a large amount of current for a

short period of time,

whereas the generator replaces this current by

charging the battery at a lower

rate for a much longer

period of time.

|

|||

|

Fig. 42-Cut-Away View of Starting Motor Drive

A multiple spring and

roller over-running mechanism, Fig. 43, similar to that of a bicycle

coaster brake, is located between

the outer part of the

clutch which is attached to the pinion and the

inner part splined to the

armature shaft.

|

|||

|

|

|||